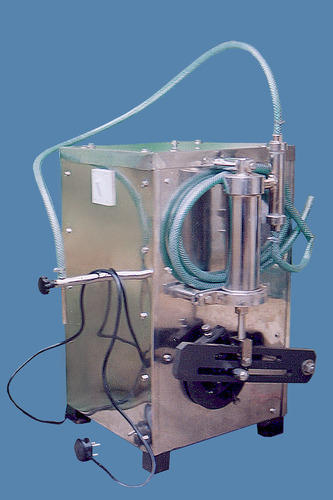

Bottle Filling Mortised Machine

Bottle Filling Mortised Machine Specification

- Glass Type

- PET, Glass, HDPE Bottles

- Speed Range

- Variable, up to 30 BPM

- Shape

- Rectangular

- Features

- Automatic Operation, Adjustable Volume, Anti-drip Nozzle, Compact Design, High Efficiency, Low Maintenance

- Temperature Resistance

- Up to 80C

- Control Type

- PLC Control

- Display Type

- Touch Screen

- Accuracy

- 1% Filling Accuracy

- Power Supply

- Electric

- Type

- Automatic Bottle Filling Mortised Machine

- Dimension (L*W*H)

- 2100 x 1400 x 1800 mm

- Equipment Type

- Filling Machine

- Equipment Materials

- Stainless Steel (SS304)

- Power

- 2.2 kW

- Voltage

- 220V / 380V, 50Hz

- Material

- Food Grade Stainless Steel

- Application

- Liquid Bottle Filling (Water, Juice, Oil, etc.)

- Capacity (Ltr)

- 1000-3000 Bottles per Hour

- Filling Range

- 200 ml - 2000 ml

- Noise Level

- Below 70 dB

- Container Height Range

- 150 mm to 350 mm

- Installation

- Floor Mounted

- Cleaning System

- CIP (Clean in Place) Compatible

- Conveyor Material

- Stainless Steel Chain

- Lubrication

- Self-Lubricating System

- Nozzles

- 4 to 12 (Customizable)

- Bottle Diameter Range

- 50-120 mm

- Weight

- Approx. 900 kg

- Container Type

- Round/Square/Custom Shape Bottles

- Safety Features

- Emergency Stop, Overload Protection

- Operation Mode

- Automatic and Semi-Automatic Options

About Bottle Filling Mortised Machine

Bottle Filling Mortised Machine

| Power Consumption | 0.5 HP |

| Driven Type | Electric |

| Usage/Application | Pharma |

| Material | Stainless Steel |

| Brand | Micro Technologies |

| Frequency | 50 Hz |

| Phase | Single Phase |

| Voltage | 230 V |

| Country of Origin | Made in India |

High Efficiency & Customization

This machine delivers exceptional throughput, handling up to 3000 bottles per hour with precision. Its customizable nozzle count and adjustable filling ranges make it suitable for varying production demands, ensuring operational flexibility and scalability for diverse industries.

Advanced Safety & Hygiene Features

Equipped with emergency stop and overload protection, this bottling machine prioritizes operator safety. Clean-In-Place (CIP) compatibility, food-grade materials, and self-lubrication contribute to hygienic operations, reduced downtime, and minimal maintenance needs.

Versatile Bottle Handling & Control

Accommodating a broad array of bottle types, shapes, and material (PET, glass, HDPE), this machine features a PLC touch screen for easy adjustment and operation. Its anti-drip nozzles and 1% filling accuracy ensure optimal product quality and precise filling.

FAQ's of Bottle Filling Mortised Machine:

Q: How does the Bottle Filling Mortised Machine ensure precise and consistent filling?

A: This machine achieves 1% filling accuracy, thanks to its PLC-controlled system and anti-drip nozzles, ensuring each container receives the correct amount of liquid, minimizing product waste and maximizing consistency.Q: What types and shapes of bottles can be filled using this machine?

A: The machine is compatible with a wide range of bottles, including PET, glass, HDPE, and custom shapes, in both round and square formats, covering diameters from 50 mm to 120 mm and heights from 150 mm to 350 mm.Q: Where can the Bottle Filling Mortised Machine be installed, and is installation complicated?

A: This floor-mounted machine is designed for easy installation in commercial or industrial settings. It comes with a compact footprint (2100 x 1400 x 1800 mm), making it suitable for manufacturing plants or bottling facilities.Q: What is the cleaning process for the machine, and is it hygienic?

A: The machine is CIP (Clean in Place) compatible and made from food-grade stainless steel (SS304), facilitating efficient, in-line cleaning procedures that meet strict hygiene standards without dismantling equipment.Q: When should you choose automatic or semi-automatic modes?

A: Select automatic mode for high-volume, continuous operations, or semi-automatic mode for flexible, lower-output runs where more operator intervention and control are needed. This flexibility supports changing production needs.Q: How does the machine's safety system work?

A: Safety features include an emergency stop button and overload protection, safeguarding operators and equipment during operation, and ensuring a secure working environment.Q: What are the primary benefits of using this bottle filling machine for distributors and manufacturers?

A: The machine offers high efficiency, significant operational flexibility, reliable hygiene standards, and low maintenance. Its robust design, variable speed, and precise controls contribute to increased productivity and reduced downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Glassware And Equipments Category

(III) Kjeldhal Digestion & Distillation Units (Combined)

Equipment Materials : Mild Steel Body with Powder Coating & Stainless Steel Heating Block

Dimension (L*W*H) : Approx. 900 x 550 x 700 mm

Application : Nitrogen Estimation in Pharmaceutical, Food, Environmental, Agricultural & Chemical Laboratories

Temperature Resistance : Up to 450C

Material : Stainless Steel, Glass, Mild Steel

Control Type : Digital Temp. Controller

Water Still (Manasty Type)

Equipment Materials : Borosilicate Glass & Stainless Steel

Dimension (L*W*H) : 500mm x 350mm x 400mm (approx.)

Application : Distillation of Water for Laboratory Use

Temperature Resistance : Up to 200C

Material : Heavy Gauge Stainless Steel (SS 304)

Control Type : Manual/Analog

Abbe Refractometer (MODEL-III)

Equipment Materials : Metallic Body with Glass Optical Parts

Dimension (L*W*H) : 220 x 100 x 250 mm (approx.)

Application : Measurement of Refractive Index and Brix of Liquids & Solids

Temperature Resistance : Up to 100C with Circulating Water Jacket

Material : Corrosion Resistant Construct with Optical Glass

Control Type : Manual Knob Adjustment

SS Mosses Ergograph

Equipment Materials : Stainless Steel

Dimension (L*W*H) : 380 mm x 512 mm x 150 mm

Application : Measurement of muscle work capacity

Temperature Resistance : Normal laboratory conditions

Material : Stainless Steel

Control Type : Manual

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese