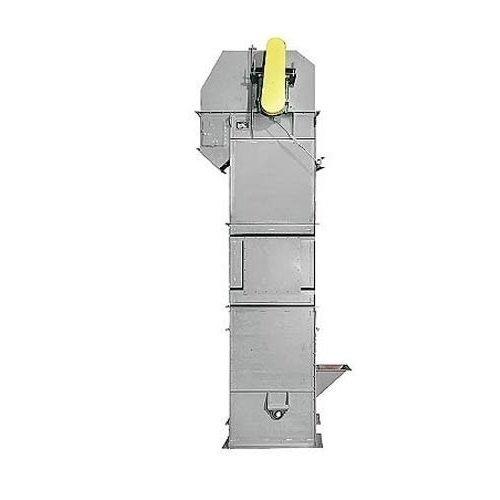

BUCKET ELEVATOR

BUCKET ELEVATOR Specification

- Features

- Efficient conveying, robust construction, minimal maintenance, modular design

- Noise Level

- Low

- Shape

- Vertical rectangular tower with buckets

- Tool Type

- Elevator

- Usage & Applications

- Factories, mills, processing plants, grain terminals, storage facilities

- Product Type

- Material Handling Equipment

- General Use

- Vertical conveying of bulk materials such as grain, fertilizer, cement, and more

- Capacity

- 1-5 Ton/hour (configurable)

- Weight (kg)

- Approx. 400-1200 kg (varies with model & capacity)

- Type

- Bucket Elevator

- Drive Type

- Electric Motor Driven

- Power

- 3-15 HP (model dependent)

- Power Source

- Electric

- Transmission Type

- Chain or Belt

- Start Method

- Automatic/Electric Start

- Machine Speed

- Adjustable/depends on specification

- Production Output

- 1-5 Ton/hour

- Material

- Mild Steel or Stainless Steel construction

- Dimension (L*W*H)

- 1800 mm x 800 mm x 3500 mm (example - customizable)

- Color

- Blue/Grey, as per manufacturers standard

- Maximum Lifting Height

- 10-40 meters

- No. of Buckets

- 20-60 (model based)

- Control System

- Automatic/Manual Switchboard Control

- Safety Features

- Anti-reverse device, overload protection, emergency stop

- Maintenance

- Easy to operate and maintain

- Installation Type

- Fixed (vertical installation)

- Operating Temperature Range

- -10°C to 60°C

- Inlet/Outlet Height

- Customized

- Bucket Material

- Mild Steel/Plastic/SS

- Conveyor Speed

- 0.5-1.5 m/s

- Bucket Size

- Standard or custom (as per needs)

- Surface Finish

- Painted or powder-coated for durability

About BUCKET ELEVATOR

BUCKET ELEVATOR: Competitive Edge & Versatile Applications

Our BUCKET ELEVATOR delivers a competitive advantage through its robust construction, modular design, and advanced safety features. The ability to customize bucket size, lifting height, and control systems makes it extremely adaptable for diverse material handling requirements. With easy operation and minimal maintenance, this elevator excels in industries such as factories, grain terminals, food processing mills, and storage facilities, offering reliable performance in every setting.

BUCKET ELEVATOR: Samples, Stock, and Market Availability

Estimate your project needs with ease-sample units of our BUCKET ELEVATOR are available upon request. Stock is readily maintained for prompt dispatch. We exchange product details and offer comprehensive support throughout purchase and installation. Our primary domestic market is India, supplied efficiently via FOB Port. The elevator is ready for immediate delivery to distributors, manufacturers, and traders, ensuring you benefit from seamless supply and dependable availability.

FAQ's of BUCKET ELEVATOR:

Q: How is the BUCKET ELEVATOR customized to fit different operation needs?

A: The BUCKET ELEVATOR offers customizable features including bucket size, lifting height, control systems, and inlet/outlet height. Options for bucket and frame material are also available, allowing the elevator to be tailored precisely to your specific material handling requirements.Q: What safety measures are integrated into the BUCKET ELEVATOR?

A: This elevator is equipped with essential safety features such as an anti-reverse device, overload protection, and an emergency stop system, ensuring secure operation during material transfer for both personnel and equipment.Q: Where is the BUCKET ELEVATOR typically used?

A: Designed for vertical conveying of bulk materials, it is widely applied in factories, food processing mills, grain storage terminals, distribution centers, and fertilizer and cement plants.Q: What is the process for installation and startup of the BUCKET ELEVATOR?

A: Installation involves fixed vertical setup, followed by connection to the electric control system and start-up using either manual or automatic switchboard controls. The process is straightforward and supported by detailed manufacturer guidelines.Q: What advantages does the BUCKET ELEVATOR offer over other material handling systems?

A: With a modular, robust construction, low noise level, minimal maintenance, and flexible customization, the BUCKET ELEVATOR delivers efficient, reliable, and cost-effective vertical bulk material transport.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Agricultural Machines & Tools Category

MOBILE CLEANING AND SORTING MACHINE (2TPH) WITH GENERATOR 20KVA

Dimension (L*W*H) : 6.5m x 2.5m x 3.0m (approx.)

Capacity : 2 Tons Per Hour (2TPH)

Material : Other, Mild Steel / Heavy Duty Steel Construction

Drive Type : Other, Mechanical / Generator Powered

Product Type : Agricultural Processing Machine

Usage & Applications : Grain/seed cleaning and sorting at farm, field or depot

SEED PRECISION DIVIDER (GAMET TYPE)

Dimension (L*W*H) : Approx. 300 x 250 x 350 mm

Capacity : Up to 1 kg (batch loading)

Material : Other, Mild steel, finished with powder coating

Drive Type : Other, Manual (hand operated)

Product Type : Seed Precision Divider (Gamet Type)

Usage & Applications : Used in labs/agriculture institutes for dividing seed samples for analysis and testing

BOD INCUBATOR (WITHOUT HUMIDITY)

Dimension (L*W*H) : Varies by model: e.g., 65x58x89 cm for 90L

Capacity : 90/150/200/300 liters (various available)

Material : Other, Inner chamber: Stainless Steel, Outer: Mild Steel powder coated

Drive Type : Other, Electric

Product Type : Laboratory Incubator

Usage & Applications : Biological oxygen demand analysis, microbiology, storage, research, environmental monitoring

GRAVITY SEPARATOR

Dimension (L*W*H) : 1900 x 1320 x 1680 mm

Capacity : 35 Ton/Hour

Material : Other, Mild Steel

Drive Type : Belt Drive

Product Type : Agricultural Machinery

Usage & Applications : Used in seed processing, grain cleaning, agriculture, and food industries

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese