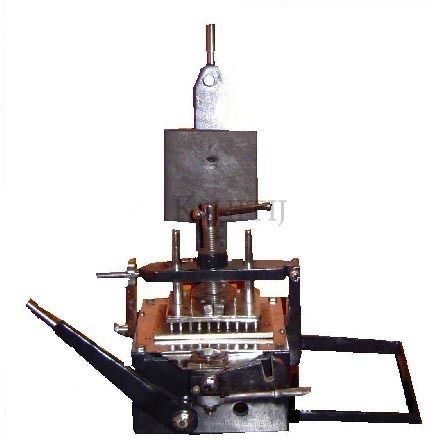

Capsule Filling Machine

Capsule Filling Machine Specification

- Accuracy

- 1%

- Speed Range

- Up to 30,000 capsules/hour

- Control Type

- Manual/Mechanical

- Temperature Resistance

- Up to 50C

- Power Supply

- Single Phase

- Display Type

- Analog

- Features

- User-friendly operation, Easy cleaning & maintenance, High productivity, GMP compliant, Safety Interlocks

- Shape

- Rectangular

- Type

- Semi-Automatic Capsule Filling Machine

- Dimension (L*W*H)

- 1250 mm x 800 mm x 1750 mm

- Equipment Type

- Capsule Filler

- Equipment Materials

- Stainless Steel 304/316

- Power

- 1.5 kW

- Voltage

- 220V

- Material

- SS 304

- Application

- Pharmaceuticals / Laboratories / Herbal

- No. of Holes per Cycle

- 300

- Noise Level

- Low

- Operation Mode

- Manual and semi-automatic

- Cleaning Mechanism

- Tool-free detachable parts

- Weight

- Approx. 250 kg

- Production Rate

- Up to 25,000 to 30,000 capsules/hour

- Filling Principle

- Tamper/Plunger assisted

- Finishing

- Mirror/Matte Finish

- Capsule Size Compatibility

- 00, 0, 1, 2, 3, 4

- Compliance Standards

- GMP / ISO 9001

About Capsule Filling Machine

Capsule Filling Machine

| Usage/Application | Pharmaceutical Industry |

| Body Material | Mild Steel |

| Brand | Micro Technologies |

| Voltage | 230 V |

| Frequency | 50 Hz |

| Phase | Single Phase |

| Power Source | Electric |

Versatile and High-Speed Capsule Filling

Crafted for scalability, this capsule filling machine efficiently processes capsule sizes 00, 0, 1, 2, 3, and 4, achieving a production rate as high as 30,000 capsules every hour. Its tamper/plunger-assisted filling principle ensures exceptional accuracy while offering flexibility to switch among different capsule types with minimal downtime.

Simplified Operation and Easy Maintenance

With user-friendly controls and tool-free detachable components, cleaning and maintenance become straightforward and quick. Whether operated manually or in semi-automatic mode, the machine allows seamless transitions, helped by safety interlocks and GMP-compliant construction to meet rigorous pharmaceutical standards.

FAQ's of Capsule Filling Machine:

Q: How does the capsule filling machine ensure accuracy during operation?

A: The machine utilizes a tamper/plunger-assisted filling principle, combined with precise mechanical controls, achieving a filling accuracy of 1%. This ensures every capsule is consistently filled to specification, minimizing product loss and maximizing quality.Q: What is the process for cleaning and maintaining the machine?

A: All contact parts are easily detachable without tools, enabling thorough cleaning between batches. Both mirror and matte finishes further facilitate easy wipe-down and sanitization, supporting GMP guidelines for pharmaceutical manufacturing.Q: When should I use the manual versus semi-automatic mode?

A: Manual mode is suitable for smaller production runs and greater operator control, while the semi-automatic mode is ideal for high-volume operation, delivering up to 30,000 capsules per hour with less manual intervention-perfect for maximizing efficiency.Q: Where is this capsule filling machine commonly used?

A: It's designed for pharmaceuticals, laboratories, and herbal product manufacturers. The machine's robust build, compliance with GMP/ISO 9001 standards, and safety features make it a trusted choice for facilities focused on hygiene and quality in India and beyond.Q: What are the benefits of choosing this particular capsule filling machine?

A: Key benefits include high productivity, low noise levels, user-friendly operation, easy maintenance, robust stainless-steel construction, temperature resistance up to 50C, and adherence to global safety and quality standards. This makes it a versatile and reliable solution for various production settings.Q: How does the cleaning mechanism promote ease of use?

A: The tool-free, quick-detach system allows operators to disassemble and reassemble parts rapidly, streamlining end-of-batch cleaning and maintenance, reducing downtime, and lowering the risk of cross-contamination.Q: What is included in the control and display system of the machine?

A: The machine features manual and mechanical controls with an analog display. This simple yet efficient design offers straightforward adjustment and monitoring, suitable for use in environments where reliability and ease of use are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Glassware And Equipments Category

Vortex Shaker/ Cyclo Mixer (Test Tube Shaker)

Equipment Materials : Body MS Powder Coated, Platform Rubber Cup

Control Type : Touch and continuous mode

Material : Mild Steel body with rubber cup

Equipment Type : Laboratory Vortex Mixer

Features : Antivibration base, robust design, chemical resistant rubber cup, easy tube placement

Dimension (L*W*H) : Approx. 120 mm x 120 mm x 170 mm

Load Measurement Trainer Module

Equipment Materials : Mild Steel Frame with Powder Coating

Control Type : Digital

Material : Mild Steel and Electronic Components

Equipment Type : Training Module

Features : Portable, UserFriendly Controls, Calibration Facility, Onboard Loading Mechanism

Dimension (L*W*H) : 510 mm x 400 mm x 160 mm

Electro Convulsometer

Equipment Materials : Stainless Steel & ABS Body

Control Type : Pushbutton & Knob Controls

Material : ABS Plastic, Stainless Steel

Equipment Type : Laboratory & Clinical Instrument

Features : Adjustable current, digital/analog meter, precise timing, safety features, compact design

Dimension (L*W*H) : 210 mm x 175 mm x 90 mm (approx.)

Student Perimeter

Equipment Materials : Metal with plastic components

Control Type : Manual

Material : Sturdy metal base, plastic arc

Equipment Type : Ophthalmic/Optometry Lab Equipment

Features : Portable, lightweight, easy to handle, durable

Dimension (L*W*H) : 45 cm x 35 cm x 35 cm (approx)

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese