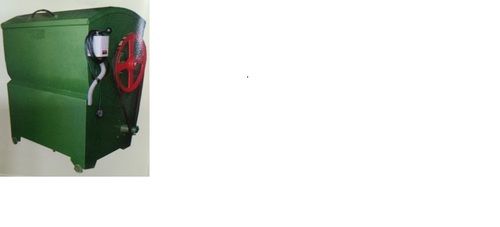

HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL

Price 70000.0 INR/ Piece

HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL Specification

- Load Capacity

- 30 kg to 120 kg

- Finish

- Corrosion Resistant, Industrial Grade

- Material

- Outer Body: Mild Steel (M.S.) Sheet, Inner Drum (Tank) & Rutter: Stainless Steel

- Shape

- Rectangular Cabinet with Cylindrical Inner Drum

- Thickness

- M.S. Sheet - 2.5 mm, Stainless Steel Drum & Rutter - 2.0 mm

- Surface Treatment

- Powder Coated (Outer Body), Polished Finish (Inner Drum)

- Standard

- IS 302-2-7 & ASTM A240 (for Stainless Steel)

- Application

- Heavy Duty Commercial Laundry Hotels, Hospitals, Industrial Laundries

- Mounting Type

- Fixed or Shock Absorber Mounted

- Voltage Requirement

- 380V/415V, 50 Hz, 3 Phase

- Motor Power

- 3 HP to 7.5 HP (depending on model)

- Drum Length

- 600 mm to 1200 mm (as per capacity)

- Drum Diameter

- Up to 1000 mm (customized as per model)

- Drive System

- Direct/Chain Drive with Heavy Duty Belt

- Door Type

- Front Loading with Secure Safety Lock

- Bearings

- Heavy Duty, Double Ball Bearing Type

- Control Panel

- Digital/Manual Control Panel with Timer

- Overall Dimension

- As per machine capacity (customized)

- Rutter Type

- Lifting Rutter, Stainless Steel, for Efficient Agitation

HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Paypal, Cheque

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Asia, Australia, Central America, North America, Africa

About HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL

Body 14 gage M.S. Sheet Size, 18"x23" Wooden Rutter& Stainless Steel Jali & Inner Drum Stainless Steel (Tank),Motor H.P. Single Phase Desi. RPM 1440, Time 15/20Minutes & Capacity 15 Clothes (Pents & Shirts) at a time(10kg.).

Body 14 gage M.S. Sheet Size, 21"x26" Wooden Rutter &Stainless Steel Jali & Inner Drum Stainless Steel (Tank),Motor 1 H.P. Single Phase Desi, RPM 1440, Time 15/20Minutes & Capacity 25 Clothes (Pents & Shirts) at a time(15kg.)

Body 14 gage M.S. Sheet Size, 24"x30" WoodenRutter & Stainless Steel Jali & Inner Drum Stainless Steel (Tank),Motor 2 H.P. Single Phase Desi, RPM 1440, Time 25/30 Minutes & Capacity 40Clothes (Pents & Shirts) at a time, (20kg.) Double Belts & Pullies.

Body 14 gage M.S. Sheet Size, 24"x36" Wooden Rutter& Stainless Steel Jali & Inner Drum Stainless Steel (Tank), Motor 2H.P. Single Phase Crompton Greaves, RPM 1440, Time 25/30 Minutes & Capacity45 Clothes (Pents & Shirts) at a time (25kg.). DoubleBelts &Pullies.

Robust Construction for Intensive Use

Engineered with an M.S. sheet outer body and stainless steel inner drum and rutter, this laundry machine promises enhanced strength and corrosion resistance. Powder coating and a polished finish protect against industrial wear, ensuring longevity even in busy commercial settings. Suitable for varied institutional and industrial requirements, it meets IS 302-2-7 and ASTM A240 standards for reliability.

Customizable Capacity and Dimensions

Drum diameters and lengths are tailored according to operational needs, accommodating up to 120 kg of laundry per cycle. The rectangular cabinet paired with a cylindrical inner drum allows users to select dimensions that align with specific capacity demands, optimizing throughput for hotels, hospitals, or large laundries.

Advanced Control and Safety Features

This machine supports both digital and manual control panels, complete with a timer for flexible operation. The secure front-loading door with safety locking mechanisms offers user protection. Heavy-duty bearings and adjustable shock absorber mounting options further enhance stability and vibration control during high-capacity cycles.

FAQ's of HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL:

Q: How does the lifting rutter enhance laundry processing in this machine?

A: The lifting rutter, crafted from stainless steel, facilitates efficient agitation by gently lifting and moving laundry through water and detergent. This design ensures optimal cleaning performance, helps prevent fabric damage, and boosts wash quality for high-volume commercial applications.Q: What are the customization options for drum size and capacity?

A: Drum diameter can be customized up to 1000 mm and length from 600 mm to 1200 mm based on model and required load capacities, which range from 30 kg to 120 kg. These options allow businesses to tailor the machine dimensions to their specific operational needs.Q: When should I choose direct drive over chain drive for the machine?

A: Direct drive systems are preferable for quieter, high-efficiency operations with minimal maintenance, suitable for environments prioritizing smooth performance. Chain drive, paired with a heavy-duty belt, is ideal for demanding conditions where handling heavier loads and durability are crucial.Q: What materials are used in constructing the outer and inner parts of the machine?

A: The outer body is engineered from 2.5 mm thick mild steel (M.S.) sheet with powder coating for enhanced corrosion resistance. The inner drum (tank) and rutter utilize 2.0 mm thick stainless steel, which is polished for hygiene and longevity.Q: Where is this heavy duty laundry machine typically used?

A: This industrial-grade machine is designed for large-scale laundry applications, such as hotels, hospitals, industrial laundries, and other commercial facilities that demand reliable, high-capacity laundry solutions.Q: What safety and control features are included in the machine?

A: It features a front-loading door with a secure safety lock, a choice between digital or manual control panels with a timer, and mounting options including fixed and shock absorber setups. These attributes ensure operational safety, convenience, and efficient cycle management.Q: How does the machine benefit commercial laundry operations?

A: Its sturdy construction, customizable capacity, industrial-grade finish, and standards compliance ensure dependable performance even under rigorous daily use. The machine's efficient agitation and corrosion resistance promote cleaner results, reduce maintenance, and enhance productivity for commercial laundry enterprises.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipette Washer Category

HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL

Minimum Order Quantity : 5 Pieces

Thickness : Outer Body: 1.5 mm, Rutter: 1.2 mm

Application : Commercial laundry equipment, industrial washing operations

Shape : Rectangular with reinforced edges

Material : Outer Body: Stainless Steel, Wooden Rutter: Stainless Steel

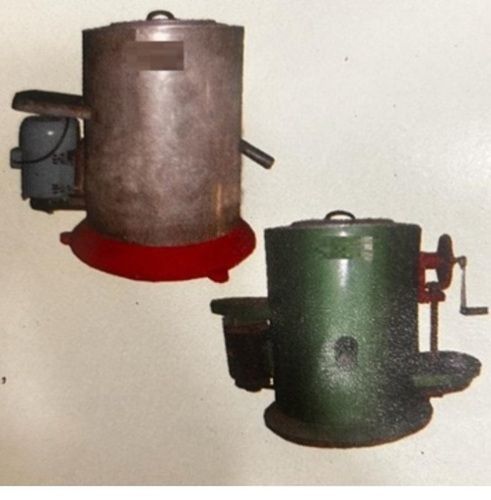

HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL

Minimum Order Quantity : 5 Pieces

Thickness : 2 4 mm (Approximate, as per industrial standard)

Application : Hydro extraction and drying in textile, laundry, and dyeing industries

Shape : Cylindrical

Material : Stainless Steel (Outer Body and Spinning Drum)

Pipette Washer (Automatic)

Thickness : 23 mm (Body)

Application : Automatic Pipette Washing & Sterilizing

Shape : Cylindrical Vertical Vessel

Material : Stainless Steel, Borosilicate Glass

Automatic Pipette Washer

Thickness : Standard gauge thickness

Application : Automatic cleaning of pipettes

Shape : Cylindrical

Material : Stainless Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese