HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL

HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL Specification

- Finish

- Mirror / Matt Finish (as per requirement)

- Load Capacity

- 25 kg 60 kg (depending on model configuration)

- Material

- Stainless Steel (Outer Body and Spinning Drum)

- Shape

- Cylindrical

- Thickness

- 2 - 4 mm (Approximate, as per industrial standard)

- Surface Treatment

- Polished

- Standard

- Industrial Grade / Customization Available

- Application

- Hydro extraction and drying in textile, laundry, and dyeing industries

- Voltage

- 415V, 50Hz (Three Phase)

- Discharge Type

- Top Loading

- Dimension

- Customizable as per requirement

- Motor Power

- 2 HP to 5 HP (Three Phase)

- Mounting

- Heavy-duty legs with anti-vibration pads

- Drum Speed

- Approx. 1400 RPM

- Safety Features

- Safety locking system, Vibration absorber

- Drive Type

- Belt Driven

- Control Panel

- Semi-automatic / Automatic (Optional)

- Noise Level

- Low Noise Operation

HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cheque, Paypal

- Main Export Market(s)

- Western Europe, Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe

About HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL

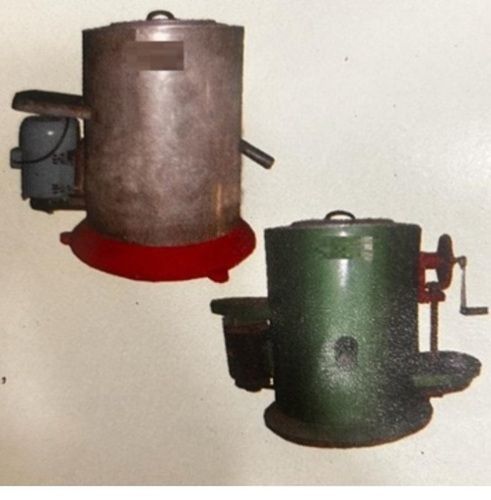

Body 14 gage Stainless Steel Size Jali 12"x15" Stainless Steel,Motor H.P. Single Phase (Desi). RPM 1440, Time 3 Minutes &Capacity 15 Clothes (Pents & Shirts) at a time (10kg.). AllumiBody 14 gage Stainless Steel Size Jali 12"x16" Stainless Steel,Motor 1 H.P. Single Phase (Desi), RPM 1440, Time 3 Minutes &Capacity 20 Clothes (Pents & Shirts) at a time (12kg.).

Body 14 gage Stainless Steel Size Jali 13"x17" Stainless Steel,Motor 1 H.P. Single Phase (Desi), RPM 1440, Time 3 Minutes &Capacity 25 Clothes (Pents & Shirts) at a time (15kg.).

Body 14 gage Stainless Steel Size Jali 13"x18" Stainless Steel,Motor 2 H.P. Single Phase (Desi),RPM 1440, Time 3 Minutes & Capacity 30 to 35 Clothes(Pents & Shirts) at a time (20kg.).

Body 14 gage Stainless Steel Size Jali 13"x20" Stainless Steel, Motor 2 H.P. Single Phase(Desi), RPM 1440, Time 3 Minutes & Capacity 40 Clothes (Pents & Shirts) at a time (25kg.).

Body 14 gage Stainless Steel Size Jali 12"x15" Stainless Steel, Hand Hydro Extractor &Capacity 15 Clothes (Pents & Shirts) at a time (10kg.).

Body 14 gage Stainless Steel Size Jali 12"x16" Stainless Steel, Hand Hydro Extractor &Capacity 20 Clothes (Pents & Shirts) at a time (12kg.). Body 14 gage Stainless Steel Size Jali 12"x15" Stainless Steel, Hand Hydro Extractor &Motor H.P. Single Phase (Desi) (Combined), RPM 1440, Time 3 Minutes & Capacity 15Clothes (Pents & Shirts) at a time (10kg.).

Body 14 gage Stainless Steel Size Jali 12"x16" StainlessSteel, Hand Hydro Extractor, & Motor 1 H.P. Single Phase(Desi) (Combined), RPM 1440, Time 3 Minutes & Capacity20 Clothes (Pents & Shirts) at a time (12kg.).

Precision Engineering and Construction

Crafted entirely with high-grade stainless steel for both the outer body and spinning drum, this hydro extractor guarantees exceptional durability and corrosion resistance. The cylindrical structure, with material thickness between 2 to 4 mm, provides unwavering strength and longevity. Finished to a mirror shine or matt appearance, its polished surface is tailored to industrial standards or customer specifications, ensuring maximum hygiene and easy maintenance.

Outstanding Performance and Safety

Designed for reliability, the hydro extractor operates at a drum speed of roughly 1400 RPM, powered by a robust three-phase motor (2 HP to 5 HP). Its advanced safety locking system and heavy-duty anti-vibration mounts enable low-noise operation, even under intensive workloads. Optional semi-automatic or automatic controls deliver user flexibility, while the top-loading, belt-driven mechanism ensures simple and efficient loading and discharge of materials.

Versatility Across Industries

This hydro extractor is expertly suited for hydro extraction and drying processes in textile manufacturing, laundry services, and dyeing facilities. With customizable load capacities (25 kg to 60 kg), voltage compatibility (415V, 50Hz), and adaptable dimensions, it fits seamlessly into various operational settings. The machine's industrial-grade build ensures consistent output, minimizing downtime while maximizing fabric throughput.

FAQ's of HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL:

Q: How does the HYDRO EXTRACTOR (DRIER) work in textile and laundry industries?

A: The hydro extractor uses centrifugal force generated by a spinning drum at around 1400 RPM to expel excess water from fabrics. This rapid extraction process significantly shortens drying times compared to traditional methods, making it ideal for textile manufacturing, laundry services, and dyeing operations.Q: What materials are used in the construction of the machine?

A: Both the outer body and spinning drum are constructed entirely from high-quality stainless steel, offering excellent resistance to corrosion and wear. The thickness is approximately 2-4 mm, ensuring durability even under heavy industrial usage.Q: When should I consider customizing the dimensions or load capacity of the extractor?

A: Customization is recommended when your operational requirements involve specific space constraints or particular load capacities. The machine's design allows for tailored dimensions and load handling (from 25 kg to 60 kg), adapting conveniently to varied industrial setups and workflow needs.Q: Where can this hydro extractor be installed?

A: This machine is suitable for installation in textile mills, commercial laundries, dyeing units, and any setting demanding high-efficiency fabric water extraction. It can be supplied across India, whether directly from a manufacturer, distributor, supplier, exporter, or trader.Q: What benefits does the safety locking system and vibration absorber provide?

A: The advanced safety locking system and vibration absorber enhance operational security by preventing accidental lid opening and minimizing vibrations during high-speed cycles. These features contribute to both workplace safety and low-noise functionality, thus ensuring pleasant and safe usage.Q: How is the control panel operated, and what are the options?

A: You can choose between semi-automatic and fully automatic control panel options. Both provide intuitive management of spin cycles and safety features, allowing operators to select settings by simple controls or enabling automated cycles for streamlined production.Q: What is the typical process for using this hydro extractor for laundry or dyeing applications?

A: Load your material into the spinning drum through the top-loading hatch, select your preferred settings on the control panel, and initiate the spin cycle. The machine's high-speed centrifugal action will rapidly extract water, after which you simply unload the processed fabrics, ready for the next stage of drying or finishing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipette Washer Category

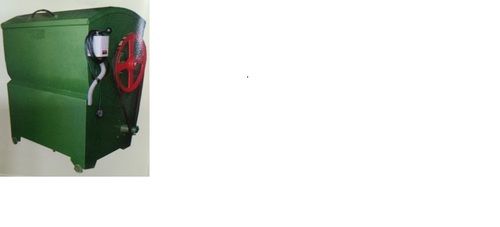

HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL

Minimum Order Quantity : 5 Pieces

Surface Treatment : Powder Coated (Outer Body), Polished Finish (Inner Drum)

Standard : IS 30227 & ASTM A240 (for Stainless Steel)

Material : Outer Body: Mild Steel (M.S.) Sheet, Inner Drum (Tank) & Rutter: Stainless Steel

Thickness : M.S. Sheet 2.5 mm, Stainless Steel Drum & Rutter 2.0 mm

Application : Heavy Duty Commercial Laundry Hotels, Hospitals, Industrial Laundries

HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL

Minimum Order Quantity : 5 Pieces

Surface Treatment : Polished and anticorrosive coating

Standard : Industrial Grade IS:6911/ASTMA240

Material : Outer Body: Stainless Steel, Wooden Rutter: Stainless Steel

Thickness : Outer Body: 1.5 mm, Rutter: 1.2 mm

Application : Commercial laundry equipment, industrial washing operations

Pipette Washer (Automatic)

Surface Treatment : Polished and Corrosion Resistant

Standard : Laboratory Grade, ISO Certified

Material : Stainless Steel, Borosilicate Glass

Thickness : 23 mm (Body)

Application : Automatic Pipette Washing & Sterilizing

Automatic Pipette Washer

Surface Treatment : Polished

Standard : Laboratory Equipment Standards

Material : Stainless Steel

Thickness : Standard gauge thickness

Application : Automatic cleaning of pipettes

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese