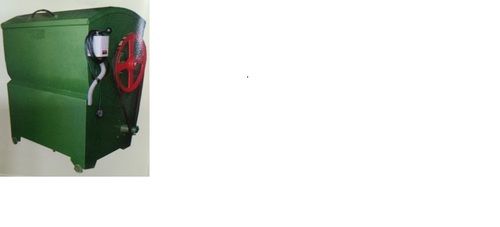

HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL

HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL Specification

- Finish

- Glossy mirror finish

- Load Capacity

- Up to 100 kg per cycle

- Material

- Outer Body: Stainless Steel, Wooden Rutter: Stainless Steel

- Shape

- Rectangular with reinforced edges

- Thickness

- Outer Body: 1.5 mm, Rutter: 1.2 mm

- Surface Treatment

- Polished and anti-corrosive coating

- Standard

- Industrial Grade IS:6911/ASTM-A240

- Application

- Commercial laundry equipment, industrial washing operations

- Rutter Material

- High-grade stainless steel with wooden reinforced design

- Noise Level

- Below 65 dB

- Power Requirement

- Suitable for 3-phase, 440V industrial power lines

- Lid Type

- Heavy-duty stainless steel hinged lid

- Weight

- Net 105 kg

- Corrosion Resistance

- Excellent (rated for high-humidity environments)

- Manufacturing Process

- Sheet metal pressed, CNC welded, hand-polished

- Accessories Included

- Stainless steel inlet/outlet pipe, vibration dampers

- Mount Type

- Floor mounted

- Dimensions

- Width 940 mm, Height 1200 mm, Depth 820 mm

HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Paypal, Cheque

- Main Export Market(s)

- Western Europe, Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe

About HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL

Body 14 gage Stainless Steel Size, 18"x23" Wooden Rutter& Stainless Steel Jali & Motor H.P. Single Phase Desi, RPM 1440,Time 15/20 Minutes & Capacity 15 Clothes (Pents & Shirts) at atime (10kg.).

Body 14 gage Stainless Steel Size, 21"x26" Wooden Rutter &Stainless Steel Jali & Motor 1 H.P. Single Phase Desi, RPM 1440,Time 15/20 Minutes & Capacity 25 Clothes (Pents & Shirts) at atime (15kg.).

Body 14 gage Stainless Steel Size, 24"x30" WoodenRutter & Stainless Steel Jali & Motor 2 H.P. Single Phase Desi, RPM1440, Time 25/30 Minutes & Capacity 40 Clothes (Pents & Shirts) at atime, (20kg.) Double Belts & Pullies.

Body 14 gage Stainless Steel Size, 24"x36" WoodenRutter & Stainless Steel Jali & Motor 2 .. Single Phas Phase CromptonGreaves, RPM 1440, Time 25/30 Minutes & Capacity 45 Clothes (Pents &Shirts) at a time (25kg.). Double Belts & Pullies.

Sturdy Construction & Industrial Grade Build

The outer body is manufactured using precision sheet metal pressing, CNC welding, and meticulous hand-polishing, resulting in an industrial-grade machine designed for rigorous commercial use. With a 1.5 mm thick stainless steel outer shell and a 1.2 mm reinforced rutter, the structure is robust, resistant to corrosion, and suitable for high-humidity laundry environments.

Optimized for High Load and Smooth Operation

Supporting up to 100 kg per cycle, this machine is equipped with a heavy-duty stainless steel lid and advanced noise dampening components, ensuring efficient washing with noise levels below 65 dB. The included vibration dampers and solid floor-mounted design provide stable, low-vibration operation even at maximum loads.

Superior Corrosion Resistance & Easy Maintenance

A polished mirror finish combined with anti-corrosive coating guarantees longevity and easy cleaning, essential for industrial settings. Manufactured to stringent IS:6911/ASTM-A240 standards, the machine is built to withstand continuous, heavy-duty use while maintaining its glossy appearance and performance.

FAQ's of HEAVY DUTY LAUNDRY MACHINE OUTER BODY STAINLESS STEEL, & WOODEN RUTTER OF STAINLESS STEEL:

Q: How is the outer body and rutter constructed for enhanced durability?

A: The outer body is crafted from 1.5 mm industrial-grade stainless steel, while the rutter combines high-grade stainless steel with a wooden reinforced design at 1.2 mm thickness. Both undergo advanced sheet metal pressing, CNC welding, and hand-polishing, resulting in superior strength and corrosion resistance for demanding laundry environments.Q: What is the recommended power supply for this laundry machine?

A: This machine is engineered for industrial use, requiring a 3-phase, 440V power supply. Proper connection to commercial-grade power lines ensures optimal performance and longevity in high-capacity laundry applications.Q: Where is this laundry machine best utilized?

A: The machine is ideal for commercial laundries, hotels, hospitals, and industrial washing operations, particularly in environments where high humidity and frequent heavy-duty use are common. Its corrosion-resistant and robust structure makes it suitable for facilities across India.Q: What accessories are included with the machine upon purchase?

A: Each unit comes with robust stainless steel inlet and outlet pipes, along with vibration dampers. These accessories facilitate seamless installation, minimize operational noise, and maximize the efficiency and safety of daily washing cycles.Q: How can users benefit from its corrosion resistance and noise reduction features?

A: Its excellent corrosion resistance ensures reliability and minimal maintenance, even in damp or humid conditions. With noise levels below 65 dB and built-in vibration dampers, users experience a quieter work environment, reducing stress and promoting workplace safety during prolonged operation.Q: What is the process for cleaning and maintaining this laundry machine?

A: Thanks to its polished, mirror finish and anti-corrosive coating, the machine is easy to keep clean. Routine wiping with a damp cloth and periodic inspection of moving parts and vibration dampers are generally sufficient, helping maintain performance and extend service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipette Washer Category

HEAVY DUTY LAUNDRY MACHINE OUTER BODY M.S. SHEET & INNER DRUM (TANK) & RUTTER OF STAINLESS STEEL

Minimum Order Quantity : 5 Pieces

Thickness : M.S. Sheet 2.5 mm, Stainless Steel Drum & Rutter 2.0 mm

Surface Treatment : Powder Coated (Outer Body), Polished Finish (Inner Drum)

Application : Heavy Duty Commercial Laundry Hotels, Hospitals, Industrial Laundries

Shape : Rectangular Cabinet with Cylindrical Inner Drum

Material : Outer Body: Mild Steel (M.S.) Sheet, Inner Drum (Tank) & Rutter: Stainless Steel

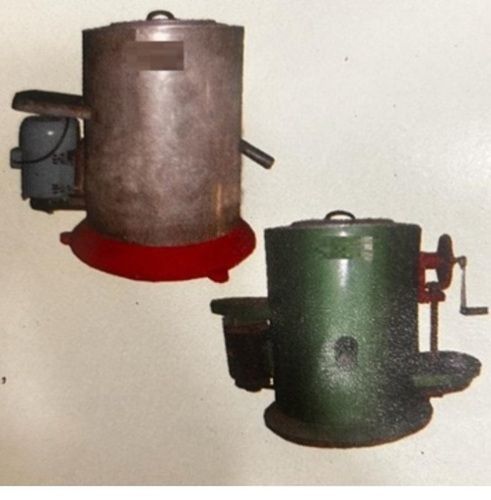

HYDRO EXTRACTOR (DRIER) OUTER BODY STAINLESS STEEL, SPINNING DRUM OF STAINLESS STEEL

Minimum Order Quantity : 5 Pieces

Thickness : 2 4 mm (Approximate, as per industrial standard)

Surface Treatment : Polished

Application : Hydro extraction and drying in textile, laundry, and dyeing industries

Shape : Cylindrical

Material : Stainless Steel (Outer Body and Spinning Drum)

Pipette Washer (Automatic)

Thickness : 23 mm (Body)

Surface Treatment : Polished and Corrosion Resistant

Application : Automatic Pipette Washing & Sterilizing

Shape : Cylindrical Vertical Vessel

Material : Stainless Steel, Borosilicate Glass

Automatic Pipette Washer

Thickness : Standard gauge thickness

Surface Treatment : Polished

Application : Automatic cleaning of pipettes

Shape : Cylindrical

Material : Stainless Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese