मà¥à¤à¥à¤¸à¤µà¥à¤² ठà¤à¤¸ नà¥à¤¡à¤² दà¥à¤µà¤¾à¤°à¤¾ तार à¤à¥ à¤à¤ à¥à¤°à¤¤à¤¾ à¤à¥ मापाà¤à¤ à¤à¤¾ निरà¥à¤§à¤¾à¤°à¤£

मà¥à¤à¥à¤¸à¤µà¥à¤² ठà¤à¤¸ नà¥à¤¡à¤² दà¥à¤µà¤¾à¤°à¤¾ तार à¤à¥ à¤à¤ à¥à¤°à¤¤à¤¾ à¤à¥ मापाà¤à¤ à¤à¤¾ निरà¥à¤§à¤¾à¤°à¤£ Specification

- टाइप करें

- मटेरियल

- Stainless Steel body with precision wire

- साइज

- Standard experimental size (needle length approx. 30 cm)

- इनपुट वोल्टेज

- Not required (manual operation)

- रंग

- Silver (metallic finish)

- आयाम (एल* डब्ल्यू* एच)

- Approx. 35 cm x 15 cm x 15 cm

- क्षमता

- Designed for wires of diameter: 0.3 mm to 0.6 mm

- शोर का स्तर

- Silent/manual operation

- Weight Set Capacity

- Supports up to total load of 500 g

- Compliance

- Conforms to standard laboratory experiment norms

- Supported Wire Materials

- Copper, steel, brass wires

- Measurement Range

- Supports measurements for modulus of rigidity (η) in the range of common wire materials

- Operating Environment

- Indoor, laboratory conditions

- Calibration

- Factory calibrated for standard experimental accuracy

- Usage

- Educational and research laboratory apparatus for physics experiments

- Experimental Setup

- Comprises hollow cylindrical needle, wire suspension, loading pan, and stable base

- Accessories Included

- Includes set of weights (50 g, 100 g, 200 g), wire clamps, and support stand

- Scale Type

- Mounted with high-precision graduated scale for angular readings

- Display Type

- Manual dial/scale reading

- Model Number

- MW-2024

About मà¥à¤à¥à¤¸à¤µà¥à¤² ठà¤à¤¸ नà¥à¤¡à¤² दà¥à¤µà¤¾à¤°à¤¾ तार à¤à¥ à¤à¤ à¥à¤°à¤¤à¤¾ à¤à¥ मापाà¤à¤ à¤à¤¾ निरà¥à¤§à¤¾à¤°à¤£

Versatile Laboratory Use and Applications

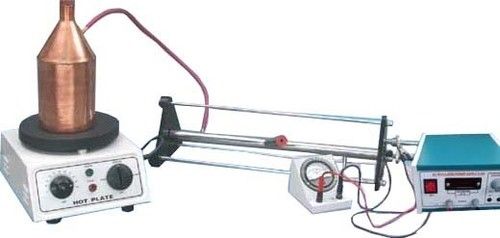

The DETERMINATION OF MODULUS OF RIGIDITY '' OF WIRE BY MAXWELL'S NEEDLE is expertly designed for precise use in educational and research laboratories. It enables students and scientists to measure the modulus of rigidity of various wire materials such as copper, steel, and brass. This apparatus is widely applied in physics departments of schools, colleges, universities, and research centers, where practical experimentation with physical properties is essential for learning and innovation.

Export Markets, Supply, and Packaging

Delivered to major export markets across Asia, Africa, and beyond, this apparatus is packaged with careful attention to safety and accountability. Transportation timelines are estimated based on location, with prompt dispatch for both bulk and individual orders. With reliable supply ability through established distributor, exporter, and manufacturer channels in India, each unit is professionally packed to ensure secure arrival, supporting both domestic and international academic needs.

FAQ's of DETERMINATION OF MODULUS OF RIGIDITY aIa OF WIRE BY MAXWELLaS NEEDLE:

Q: How does the Maxwell's Needle apparatus help in determining the modulus of rigidity of wires?

A: The Maxwell's Needle apparatus measures small angular deflections of a wire under load, allowing accurate calculation of the modulus of rigidity () for specific materials like copper, steel, or brass. Its high-precision graduated scale ensures reliable and repeatable results.Q: What wire materials and diameters are supported by this apparatus?

A: This apparatus is designed to test copper, steel, and brass wires with diameters ranging from 0.3 mm to 0.6 mm, making it versatile for various educational and research applications.Q: Where can this apparatus be effectively used?

A: It is mainly used in school and college physics laboratories, university research departments, and educational training centers that conduct experiments involving wire torsion and modulus measurements.Q: What are the advantages of using a manually operated, silent apparatus like this?

A: Manual operation ensures silent, disturbance-free use in laboratories. The lack of electrical requirements makes it convenient and safe, while factory calibration guarantees standard experimental accuracy.Q: What items are included in the package upon delivery?

A: Each unit is delivered with essential accessories, including a set of weights (50 g, 100 g, 200 g), wire clamps, a support stand, a stable base, and documentation, ensuring a comprehensive experimental setup.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in नमी Category

किसी दिए गए धातु रॉड या रैखिक विस्तार उपकरण के थर्मल रैखिक विस्तार के गुणांक को निर्धारित करें

मटेरियल : Metallic (with mild steel or brass rod)

शोर का स्तर : N/A (Silent operation)

आयाम (एल* डब्ल्यू* एच) : Approx. 450 mm x 160 mm x 100 mm

साइज : Standard laboratory size

रंग : Metallic silver with painted base

टाइप करें : ,

नर्सिंग चार्ट्स

मटेरियल : Premium Quality Laminated Paper

शोर का स्तर : Silent – Noise Free

आयाम (एल* डब्ल्यू* एच) : Approximately 70 x 50 cm

साइज : Large (as per hospital standard)

रंग : Multicolor

टाइप करें : ,

SCR सिंगल फेज हाफ-फुल कंट्रोल्ड ब्रिज कन्वर्टर

मटेरियल : Industrial Grade Components, Metal Chassis

शोर का स्तर : Low, Silent in Operation

आयाम (एल* डब्ल्यू* एच) : 470mm x 300mm x 140mm (Approx.)

साइज : Standard Lab Size

रंग : White with Blue/Black Panel Accents

टाइप करें : ,

SCR सिंगल फेज फुल कंट्रोल्ड रेक्टिफायर

मटेरियल : Metal Body with Insulated Base

शोर का स्तर : Low

आयाम (एल* डब्ल्यू* एच) : As per Design Specification

साइज : Standard Industrial Size

रंग : BlueGray (as shown in image)

टाइप करें : ,

जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese