Level Control Loop Trainer

Level Control Loop Trainer Specification

- Control Type

- PID (ProportionalIntegralDerivative)

- Power Supply

- 230V AC

- Features

- Real-time process control, observation window, industrial grade components

- Temperature Resistance

- Up to 80C

- Glass Type

- Transparent level tube

- Accuracy

- 1%

- Display Type

- Digital LCD display

- Shape

- Rectangular

- Type

- Level Control Loop Trainer

- Dimension (L*W*H)

- 1050mm x 600mm x 800mm

- Equipment Type

- Control Loop Trainer

- Equipment Materials

- MS powder coated body, SS304 tank

- Power

- 230V AC, 50Hz, 1 Phase

- Voltage

- 230V

- Material

- Mild Steel frame and Stainless Steel tank

- Application

- Educational laboratory, industrial automation training

- Capacity (Ltr)

- 10 Litres

- Ambient Temperature Range

- 5°C to 40°C

- Safety Feature

- Overload and short-circuit protection

- Inlet/Outlet Ports

- 1/2 inch BSP

- Mounting Type

- Table-top

- Sensors

- High accuracy level transmitter

- Calibration

- Factory calibrated

- Tank Measurement Scale

- Graduated

- Pump Type

- Centrifugal pump, 0.5 HP

- Controller Model

- Digital PID controller

- Training Manual

- Comprehensive included

- Flow Meter Type

- Rotameter (Acrylic Body)

- Process Data Interface

- BNC connectors for signals

- Software Support

- Process logging and analysis (optional)

About Level Control Loop Trainer

Level Control Loop Trainer

| Usage/Application | Laboratory |

| Brand | Micro Technologies |

| Control Valve | 1/2" Globe Valve (Linear) 15mm Stem Travel |

| Measuring Tank | Acrylic tank of 30cm length(5 liters capacity) |

| Water Circulation | FHP pump with necessary piping (Flexible type) |

| Source Tank | SS Tank of capacity 20 liters (approximately) |

| Actuator | Pneumatic Actuator input 3 to 15 PSI |

| I to P Converter | Input 4-20mA output 3-15 PSI |

| PC Interface Card | 16 Bit ADC (8 Ch) with 12 bit DAC interfaced with PC Through RS-232/ USB Port |

| Power Supply | 230V 50 HZ |

| Pressure Gauges | Bourdone Pressure Gauge 0 to 100 PSI -1 No., 0 to 30 PSI - 1 No |

| Manual Bypass Values | Manual 1/2" Gate Valve |

| Flow Measurement | Rotameter (1500 LPH) |

| Mounting | Mounted on a Powder Coated metal frame (Approx.650 x 500 x 750. L x B x H) |

Superior Design for Practical Learning

Built with a mild steel powder-coated body, stainless steel tank, and transparent level tubing, the Level Control Loop Trainer supports real-time observation and experimentation. The table-top mounting makes it suitable for both classroom and laboratory settings, backed by a graduated measurement scale for accurate reading and analysis.

Advanced Control and Safety Features

A digital LCD PID controller offers precise process management, while the equipment's overload and short-circuit protection maximize safety during operation. Signals are easily accessible via BNC connectors, and an observation window enhances the learning experience by making internal processes visible.

Applications in Education and Industry

This trainer is designed for practical training in educational laboratories, technical institutes, and industrial automation centers. With industrial-grade components and a capacity of 10 litres, it simulates real-world process control, making it valuable for both teaching and skill assessment.

FAQ's of Level Control Loop Trainer:

Q: How does the Level Control Loop Trainer facilitate educational training?

A: The system integrates hands-on learning with real-time process control using a digital PID controller, enabling students to observe, configure, and analyze liquid level regulation. The transparent acrylic rotameter and observation window provide clear visualization for enhanced understanding.Q: What safety features are included with this trainer?

A: To ensure operator safety, the trainer is equipped with overload and short-circuit protection, prevents electrical hazards, and allows worry-free experimentation in classroom and industrial environments.Q: Where can I use the Level Control Loop Trainer?

A: This equipment is ideal for use in educational laboratories, industrial training programs, and technical institutes. Its table-top mounting and compact design make it easy to integrate into various learning and training setups.Q: What is the process of data acquisition from the trainer?

A: Process data can be interfaced via BNC connectors for analysis. Optional software is available for process logging and analysis, supporting deeper investigation and record-keeping for training sessions.Q: When is calibration or maintenance needed?

A: The trainer is factory-calibrated and requires minimal recalibration. Routine maintenance mainly involves verifying sensor accuracy and inspecting system components, as outlined in the comprehensive training manual.Q: How does the PID controller benefit users during training?

A: The digital PID controller delivers high-precision control of liquid levels with an accuracy of 1%. This allows users to study and optimize process parameters effectively, equipping them with practical automation skills.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Glassware And Equipments Category

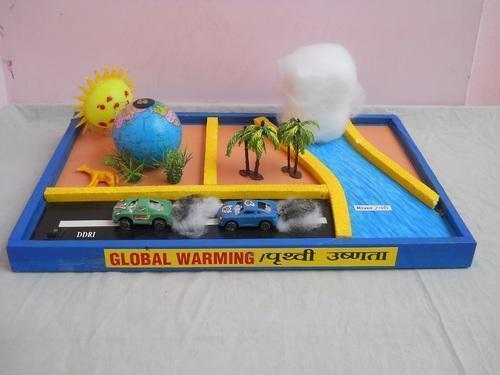

Global Warming Models

Type : Other, Educational Model

Material : High Quality Plastic and Metal

Dimension (L*W*H) : 320 x 260 x 220 mm

Shape : Rectangular

Equipment Type : Global Warming Model

Equipment Materials : Plastic, Metal, Acrylic

Hoffman's Screw Clip

Type : Other, Hoffmans Screw Clip

Material : Nickelplated Brass

Dimension (L*W*H) : Standard / Custom sizes available

Shape : Rectangular with screw mechanism

Equipment Type : Screw Clip

Equipment Materials : Metal Alloy

OCTOPUS ZOOLOGY BIOLOGY SPECIMEN

Type : Other, Zoology Biology Specimen

Material : Preserved Biological Octopus in solution

Dimension (L*W*H) : Approx. 20 cm x 10 cm x 5 cm

Shape : Rectangular Jar

Equipment Type : Specimen Bottle

Equipment Materials : Acrylic, Glass Jar

OPTICAL BENCH

Type : Other, OPTICAL BENCH

Material : Sturdy Metal Base, Steel Optics Holders

Dimension (L*W*H) : Approx. 160 cm x 12 cm x 9 cm

Shape : Rectangular/Base

Equipment Type : Laboratory Instrument

Equipment Materials : Cast Iron Base with Steel Scale

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese