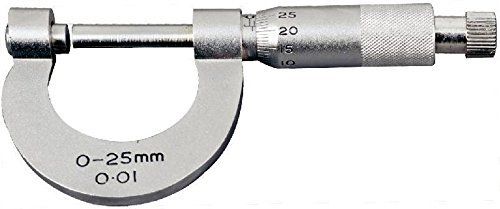

MICROMETER SCREW GAUGE FOR ENGINEERING

MICROMETER SCREW GAUGE FOR ENGINEERING Specification

- Type

- Micrometer Screw Gauge

- Material

- Stainless Steel

- Size

- 0-25 mm range

- Color

- Metallic Silver

- Dimension (L*W*H)

- Approx. 120 x 50 x 20 mm

- Capacity

- 25 mm

- Noise Level

- Silent Operation

- Application

- Precision Engineering, Laboratory, Industrial Use

- Weight

- Approx. 250 g

- Frame Finish

- Powder Coated / Painted

- Thimble Type

- Ratchet Stop

- Packaging Type

- Individual Plastic Case

- Measuring Faces

- Carbide-Tipped

- Locking Device

- Yes

- Accuracy

- ±0.01 mm

- Graduation

- 0.01 mm

About MICROMETER SCREW GAUGE FOR ENGINEERING

Versatility and Application Surface

The MICROMETER SCREW GAUGE FOR ENGINEERING is expertly designed for high-accuracy measurement in precision engineering, laboratory, and industrial environments. It excels on smooth metallic and non-metallic surfaces, offering reliable performance in applications where minuscule measurement details are pivotal. The carbide-tipped measuring faces ensure longevity even with extensive use. Used for measuring the thickness or diameter of small objects, it is indispensable in quality control and material testing workflows.

Domestic Market, Certification & Sample Policy

Serving the main domestic market across India, our micrometer meets stringent quality certifications, guaranteeing reliability. We offer sample policies that permit users to examine the gauge's performance before large-scale procurement; sample charges may apply depending on quantity and packaging options. Any exchange or return process is streamlined, and each product arrives securely packaged in an individual plastic case, ensuring it reaches you in pristine condition. Trust our certified offering for consistent quality.

FAQ's of MICROMETER SCREW GAUGE FOR ENGINEERING:

Q: How do I use the MICROMETER SCREW GAUGE FOR ENGINEERING for precise measurements?

A: To use the micrometer, place the object between the measuring faces, rotate the ratchet thimble until the object is firmly held, then read the measurement from the scale. The ratchet stop prevents over-tightening and ensures accuracy.Q: What are the main benefits of using a carbide-tipped micrometer screw gauge?

A: Carbide-tipped measuring faces enhance wear resistance and maintain their precision over extended usage, making the instrument ideal for repetitive tasks in industrial and laboratory settings.Q: Where can this micrometer screw gauge be applied effectively?

A: It is best suited for precision engineering, laboratory measurements, and industrial environments, especially for determining thickness or diameter of metals, wires, and small components.Q: What is the process for exchanging a product or requesting samples?

A: Samples may be provided-charges may apply based on sample size and packaging. For exchanges, contact customer support with your purchase details; exchanges are handled swiftly, with products returned in their original packaging.Q: When should the locking device be used?

A: The locking device should be engaged after you obtain your measurement. This secures the spindle position, allowing you to record the reading accurately without risk of movement.Q: How is the product packaged for delivery?

A: Each MICROMETER SCREW GAUGE is individually enclosed in a robust plastic case to provide maximum protection during shipping and handling, ensuring its arrival in optimal condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Humidifier Category

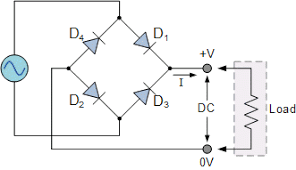

FULL WAVE RECTIFIER

Type : Other, FULL WAVE RECTIFIER

Dimension (L*W*H) : 90mm x 60mm x 20mm

Material : Highgrade semiconductor materials

Color : Black

Size : Standard module size

Noise Level : Silent Operation

THREE PHASE VOLTAGE SOURCE IGBT INVERTER USING PWM TECHINQUES

Type : Other, Three Phase Voltage Source Inverter

Dimension (L*W*H) : 340 mm x 220 mm x 105 mm

Material : Industrial Grade Electronic Components

Color : Blue/Grey

Size : Standard Laboratory Module

Noise Level : Low (<60 dB)

IC REGULATED BATTERY ELIMINATOR

Type : Other, IC Regulated Battery Eliminator

Dimension (L*W*H) : Approx. 170 x 110 x 90 mm

Material : ABS Plastic Housing, HighGrade Components

Color : Black

Size : Portable, Compact

Noise Level : Silent Operation

SPEED CONTROL OF DC MOTOR USING SINGLE PHASE HALF WAVE BRIDGE CONTROLLED BRIDGE COVERTER TRAINER (PMDC MOTOR)

Type : Other, Speed Control of DC Motor Trainer (Single Phase Half Wave Controlled Bridge Converter with PMDC Motor)

Dimension (L*W*H) : Approx. 425 mm x 340 mm x 145 mm

Material : Powder coated MS cabinet, highquality electrical and electronic components

Color : Blue and White

Size : Standard laboratory trainer size

Noise Level : < 60 dB

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese