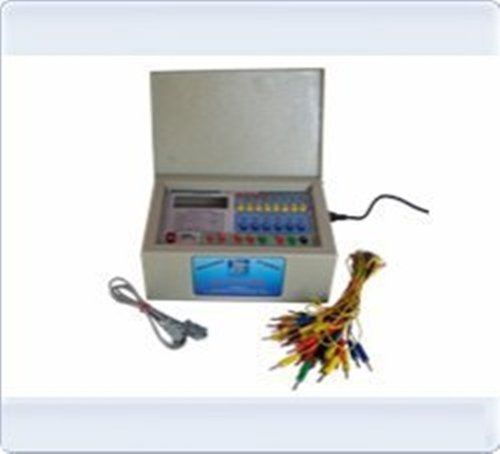

PLC Trainer UI PLC 3D

PLC Trainer UI PLC 3D Specification

- Accuracy

- 0.1 ms (response time)

- Frequency

- 50 Hz

- Features

- 3D simulation, real-time data monitoring, PLC programming

- Interface Type

- USB, Ethernet, RS-232

- Equipment Type

- PLC Training Simulator

- Specimen Size

- Standard PLC module

- Max Height

- 410 mm

- Operating Voltage

- 24 V DC, 230 V AC

- Humidity

- 10% to 90% RH

- Display Type

- LCD Display

- Automation Grade

- Automatic

- Test Range

- Multiple test sequences

- Port Size

- USB, Ethernet

- Response Time

- <1 ms

- Temperature

- 0C to 50C

- Power Supply

- 230 V AC, 50 Hz

- Measuring Range

- User programmable

- Mounting Type

- Bench-top

- Application

- Educational, Laboratory, Industrial Automation

- Number of Specimens

- Up to 3

- Resolution

- 1 ms

- Usage

- PLC Hardware and Software Training

- Capacity

- Can simulate 10+ input/output operations

- Machine Weight

- 8 kg

- Test Speed

- Variable up to 500 mm/min

- Test Width

- 320 mm

- Test Stroke

- 250 mm

- Control Mode

- Automatic and Manual

- Dimensions

- 410 mm x 320 mm x 250 mm

- Software Included

- PLC 3D Training Suite

- Model

- UI PLC 3D Trainer

- Simulation Capability

- Includes 3D virtual plant simulation

- Support PLC Brands

- Siemens, Allen Bradley, Mitsubishi

- Cooling

- Ventilated cabinet

- Demo Modes

- Pre-built training modules

- Safety

- Overload and short-circuit protection

- Communication Protocols

- Modbus, TCP/IP, Profibus

- Material

- High-strength ABS and metal

- Programming Languages

- Ladder Logic, ST, FBD, IL

About PLC Trainer UI PLC 3D

PLC Trainer UI PLC 3D

| Brand | Micro Technologies |

| Power Supply | 230V +-10% @50Hz |

| PLC Make | ABB, Siemence, Delta or Equivalent. |

| Digital Input/Output | 8 DI-24V , 6DO-24V |

| Inbuilt Power Supply | 24V @ 1A, +-15V-0-15V@500mA. |

| I/O Simulation | 4 No. Push button, 4 No. toggle switch, 6 No.LED. |

| I/O Termination | 4mm banana socket. |

| PC Interface | RS232 Serial Port with cable. |

| Enclosure | Powder coated metal box 300W X 250D X 150H |

Immersive 3D Simulation Experience

Explore interactive 3D virtual plant scenarios with the UI PLC 3D Trainer, enabling users to visualize and simulate real-world automation processes. This feature enhances understanding and engagement, preparing learners for practical field applications by replicating complex industrial environments within a safe training suite.

Versatile PLC Programming & Control

Master PLC operations with multi-language programming support, including ladder logic, structured text, FBD, and IL. The trainer enables flexible control modes and test sequences for diverse automation needs, supporting up to 10 input/output operations and providing automatic and manual control to suit various learning objectives.

Robust Design & Safety Features

Crafted from high-strength ABS and metal, the UI PLC 3D Trainer ensures durability and safety with built-in overload and short-circuit protection. Its ventilated cabinet design maintains optimal operating conditions, while variable test parameters make it suitable for a range of educational and industrial environments.

FAQ's of PLC Trainer UI PLC 3D:

Q: How do I start using the UI PLC 3D Trainer for PLC programming?

A: Begin by installing the PLC 3D Training Suite included with your trainer. Connect the device via USB or Ethernet to your computer, select your preferred PLC brand, and choose a programming language such as ladder logic, ST, FBD, or IL. The trainer guides you through practical modules and 3D simulations, making the initiation process straightforward.Q: What brands of PLCs does the UI PLC 3D Trainer support?

A: This trainer supports major PLC brands, including Siemens, Allen Bradley, and Mitsubishi. It provides a universal platform for learning and practicing control strategies across these manufacturers, ensuring compatibility for varied educational and industrial requirements.Q: When should overload and short-circuit protection features be used?

A: Overload and short-circuit protection are built into the trainer and automatically activate whenever a potentially unsafe condition occurs. These features ensure the safety of both users and equipment during hardware and software experiments.Q: Where can the UI PLC 3D Trainer be installed and used?

A: The unit's bench-top mounting design makes it suitable for educational setups, laboratories, and industrial automation workshops. Its compact dimensions and robust build facilitate easy installation in locations where hands-on PLC training is needed.Q: What is the process for simulating a virtual plant scenario?

A: Select a pre-built training module from the software suite, or customize your own scenario. Connect the trainer, set your test sequence parameters, and initiate the simulation. The trainer uses real-time data monitoring and 3D visualization to emulate real industrial processes, providing immediate feedback and detailed analysis.Q: How does the UI PLC 3D Trainer benefit learning and skill development?

A: Immersive 3D simulations, programmable test ranges, and multi-brand support offer a comprehensive learning environment. Real-time monitoring and advanced safety features enable users to practice and refine automation skills safely, preparing them for real-world applications in education and industry.Q: What communication interfaces are available for connecting the trainer?

A: The UI PLC 3D Trainer supports USB, Ethernet, and RS-232 interfaces, alongside Modbus, TCP/IP, and Profibus protocols. This ensures seamless integration with computers and other automation equipment, facilitating fast data transfer and flexible connectivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing And Measuring Equipments Category

Basic Pneumatic Trainer

Display Type : Analog/gaugebased

Automation Grade : Manual

Test Range : Basic pneumatic applications

Machine Weight : About 25 kg

Response Time : Instantaneous (manual control)

Power Supply : 230V AC, 50Hz

Displacement Measurement Trainer

Display Type : Digital LCD

Automation Grade : SemiAutomatic

Test Range : 0100 mm

Machine Weight : Approx. 5 Kg

Response Time : <200 ms

Power Supply : 230V AC, 50 Hz

Digital Kymograph

Display Type : Digital display (speed setting)

Automation Grade : SemiAutomatic

Test Range : Single or multiple channel recording

Machine Weight : 5 kg

Response Time : Instantaneous

Power Supply : 230 V AC, 50 Hz

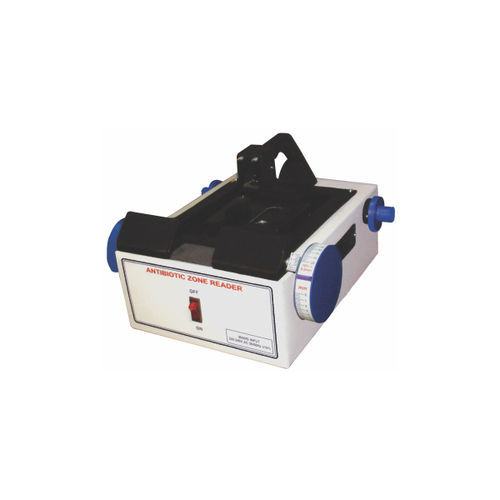

Antibiotic Zone Reader (Manually)

Display Type : Analog scale

Automation Grade : Manual

Test Range : 050 mm

Machine Weight : Approx. 2.5 kg

Response Time : Immediate/Manual

Power Supply : 230V AC 10%, 50 Hz

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese