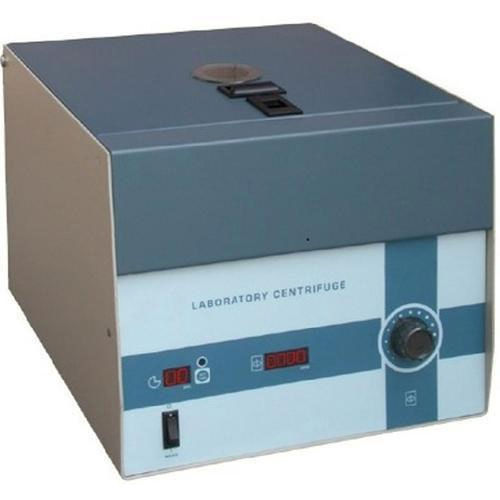

Rectangular Centrifuge

Rectangular Centrifuge Specification

- Features

- Shock Proof, Corrosion Resistant, Heavy Duty Construction

- Control Type

- Manual / Digital (Optional)

- Shape

- Rectangular

- Speed Range

- Up to 2800 RPM

- Temperature Resistance

- Up to 60C

- Display Type

- Analog / Digital (Optional)

- Accuracy

- 2%

- Power Supply

- Electric

- Type

- Rectangular Centrifuge

- Dimension (L*W*H)

- 610 mm x 460 mm x 450 mm

- Equipment Type

- Laboratory Centrifuge

- Equipment Materials

- Stainless Steel Body with Mild Steel Stand

- Power

- 220 V, 50 Hz, Single Phase

- Voltage

- 220 V

- Material

- Stainless Steel

- Application

- Liquid-solid separation, Laboratory, Pharmaceutical, Chemical processing

- Capacity (Ltr)

- 15 Ltr

- Loading Type

- Top Loading

- Safety Feature

- Lid Interlock and Safety Cut-off

- Noise Level

- < 70 dB

- Net Weight

- 58 kg

- Drum Depth

- 220 mm

- Drum Diameter

- 340 mm

- Finish

- Powder Coated for Stand, Mirror Polish for Basket

- Maximum Load Weight

- 18 kg

- Drive Mechanism

- Belt Driven

- Mounting

- Free Standing with Anti-Vibration Legs

- Basket Material

- Stainless Steel Grade 304

About Rectangular Centrifuge

Rectangular Centrifuge

| Brand | Micro Technologies |

| Voltage | 220 V |

| Phase | Single Phase |

| Frequency | 50 Hz |

| Usage/Application | Laboratory |

| Display | Digital |

| Speed | 4000-5000 rpm |

| Top Cover Material | Acrylic Sheet |

| Capacity | 4x15 ml |

| Automatic Timer | Yes |

Engineered for Precision and Versatility

Our rectangular centrifuge combines heavy-duty construction with advanced features to deliver consistent and reliable performance. The top loading design facilitates easy handling, while the stainless steel basket ensures corrosion resistance. Suitable for laboratory, chemical, and pharmaceutical use, it meets stringent requirements for accuracy (2%) and temperature resistance. With a capacity of 15 liters and a maximum load of 18 kg, it accommodates a broad range of sample sizes in diverse scientific and industrial applications.

Superior Safety and Noise Control

Safety remains paramount with an integrated lid interlock and automatic safety cut-off. The belt-driven mechanism and free-standing mount with anti-vibration legs provide stable, shockproof operation with noise levels below 70 dB. The robust combination of a mild steel stand with a powder-coated finish and a mirror-polished stainless steel basket minimizes vibration and wear, promoting both long-term reliability and occupational comfort.

FAQ's of Rectangular Centrifuge:

Q: How does the rectangular centrifuge achieve liquid-solid separation?

A: The centrifuge utilizes high-speed rotational forces, up to 2800 RPM, to separate liquid and solid components based on density differences. As the unit spins, denser particles migrate towards the basket wall, while lighter liquid components are displaced inward, resulting in effective separation.Q: What are the primary applications of this centrifuge model?

A: This centrifuge is widely used in laboratories, pharmaceutical manufacturing, and chemical processing facilities for liquid-solid separation tasks. Its heavy-duty, corrosion-resistant design makes it suitable for diverse scientific and industrial procedures where accuracy and reliability are crucial.Q: When is the best time to use the top-loading design for your separation process?

A: Top loading is optimal for tasks requiring easy sample placement and retrieval, particularly when handling large or heavy samples. It enhances accessibility, reduces manual handling time, and streamlines workflow during batch processes.Q: Where can this centrifuge be installed, and what requirements need to be met?

A: The free-standing design, equipped with anti-vibration legs, allows installation on stable laboratory or industrial floors. Ensure the area has adequate ventilation, a 220 V single-phase power supply, and protects against extreme temperature or humidity to maintain peak performance and longevity.Q: What is the benefit of the stainless steel grade 304 basket and mirror polish finish?

A: Stainless steel grade 304 provides excellent resistance to corrosion and chemical reactions, while a mirror polish significantly reduces sample adhesion and particle accumulation. This ensures easy cleaning, minimizes contamination risks, and extends the basket's operational life.Q: How do the safety features enhance operational security?

A: The lid interlock prevents the centrifuge from operating when the lid is open, and an automatic cut-off halts operation in unsafe conditions. These mechanisms protect users from accidental spillage and contact with moving parts, ensuring a safe working environment.Q: What control and display options are available, and how do they facilitate operation?

A: Users can choose between manual or digital controls, as well as analog or digital displays. These configurable options support straightforward parameter adjustments and monitoring, catering to both traditional and modern laboratory preferences for convenient and precise operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Glassware And Equipments Category

Cap Sealing Machine

Shape : Rectangular

Application : Sealing caps on bottles and containers

Features : Corrosion resistant, Easy operation, Adjustable speed, Low maintenance

Type : Other, Automatic Cap Sealing Machine

Power : 1.5 kW

Material : Stainless Steel

Lab Equipment

Shape : Rectangular

Application : Laboratory use for heating, sterilizing, mixing, and processing

Features : Corrosion resistant, portable, easy to clean

Type : Other, Lab Equipment

Power : 500 W

Material : Stainless Steel and Borosilicate Glass

Lab Willey Grinder

Shape : Rectangular

Application : Grinding of dry laboratory samples, plant material, and pharmaceuticals

Features : Easy to operate, robust construction, low maintenance, fitted with hopper and sieve, stainless steel blades

Type : Other, Willey Grinder

Power : 0.5 HP Electric Motor

Material : Mild Steel and Stainless Steel Contact Parts

Cork Borer

Shape : Cylindrical Borer

Application : Cutting cylindrical cork sections, laboratory use, sample preparation

Features : Set includes multiple diameters, sharpened edge, reamer for clearing tubes, easygrip wooden handle, corrosionresistant

Type : Other, Cork Borer

Power : Manual

Material : Nickelplated Brass with Wooden Handle

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese