Rectangular Muffle Furnace

Rectangular Muffle Furnace Specification

- Heating Capacity

- Rapid heating to maximum temperature

- Display Type

- Digital LED display

- Features

- Insulated construction, digital controls, energy efficient, rapid heating

- Control Type

- Digital temperature controller (PID)

- Power Supply

- Single Phase AC

- Shape

- Rectangular

- Accuracy

- 2C at chamber center

- Temperature Resistance

- Up to 1200C

- Type

- Rectangular Muffle Furnace

- Dimension (L*W*H)

- 225 x 100 x 100 mm (approximate)

- Equipment Type

- Laboratory Furnaces

- Equipment Materials

- Outer body made of mild steel with rustproof powder coating, ceramic insulation

- Power

- 1.2 kW

- Voltage

- 230V AC

- Material

- Mild steel (outer), high-grade ceramic (inner insulation)

- Application

- Ashing, sintering, heat treatment in laboratories and industrial use

- Capacity (Ltr)

- 2.25 Liters (approximate)

- Door Insulation

- Ceramic fiber insulation with heat proof handle

- Weight

- Approx. 22 kg

- Heating Element Type

- Kanthal wire embedded in ceramic

- Timer

- Digital timer (optional)

- Fuse Protection

- Provided for power circuit

- Temperature Uniformity

- ±5°C throughout chamber

- Maximum Operating Temperature

- 1200°C

- Cool-Down Time

- 2.5 hours (approximate)

- Safety Features

- Over-temperature protection, thermal safety cut-off

- Inner Chamber Material

- High alumina ceramic

- Chamber Volume

- 2.25L

- Operating Frequency

- 50 Hz

- Thermal Insulation Thickness

- 75 mm (approximate)

- Exterior Finish

- Powder coated rustproof mild steel

About Rectangular Muffle Furnace

Rectangular Muffle Furnace

| Brand | Micro Technologies |

| Size | 225x100x100 mm |

| Outer Shell Material | Mild Steel |

| Finish | Enamel Paint |

| Maximum Temperature | 1000 Degree C |

| Working Temperature | 940 Degree C |

| Controlled By | SUNVIC Energy Regulator |

Superior Thermal Performance and Safety

Engineered with high-alumina ceramic and ceramic fiber insulation, the furnace delivers uniform heating (5C) ideal for critical laboratory and industrial processes. Safety features such as over-temperature protection, thermal cut-off, and fuse safeguards ensure reliable and secure operation, protecting both users and samples during high-temperature applications.

Precision and Control

Equipped with a digital PID temperature controller and LED display, the furnace provides precise control up to 1200C. This ensures rapid heating, stable thermal environments, and reproducibility, essential for ashing, sintering, or heat treatment tasks. An optional digital timer enables further process automation and convenience.

Durable Construction and Efficient Design

The furnace features a rustproof powder-coated mild steel exterior, robust 75 mm insulation, and a heat-proof handle. The 2.25L chamber, contained within a compact rectangular footprint, optimizes workspace efficiency and offers rapid cool-down (approx. 2.5 hours), suitable for rigorous laboratory and industrial workflows.

FAQ's of Rectangular Muffle Furnace:

Q: How is temperature uniformity maintained throughout the muffle furnace chamber?

A: Temperature uniformity is ensured by the high-alumina ceramic chamber and Kanthal wire heaters embedded in ceramic, resulting in even heat distribution with a variance of 5C across the chamber, making it ideal for demanding laboratory applications.Q: What are the key safety features of this muffle furnace?

A: This furnace is equipped with over-temperature protection, a thermal safety cut-off system, and fuse protection for the power circuit. These features work together to prevent overheating and electrical mishaps, ensuring safe day-to-day use.Q: When should I use a muffle furnace in a laboratory or industrial setting?

A: Use the furnace for tasks such as ashing, sintering, and various heat treatment processes. It is suitable whenever consistent, high-temperature environments up to 1200C are required for reliable sample processing or material analysis.Q: Where can I install this rectangular muffle furnace?

A: It is suitable for installation in laboratories, quality control rooms, research facilities, and small-scale industrial production sites. Ensure ample ventilation and a stable, heat-resistant surface for optimal safety and performance.Q: What is the typical process for operating this muffle furnace?

A: Place your sample inside the chamber, set the desired temperature using the digital PID controller, and, if required, set the optional digital timer. The furnace rapidly heats to the setpoint, maintaining precise conditions throughout the cycle with easy-to-read LED displays.Q: How does the furnace benefit users during heat treatment processes?

A: The furnace offers rapid heating, consistent temperature control, and superior insulation, ensuring energy efficiency and reproducible results. Its robust safety mechanisms and durable design minimize downtime and improve user safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Glassware And Equipments Category

Bottle Washing Machine

Application : Washing bottles in pharmaceutical, food & beverage, chemical industries

Equipment Type : Pharma Machinery

Equipment Materials : Stainless Steel (SS 304/316)

Control Type : PLC based control

Features : Compact design, hygienic operation, low maintenance, adjustable bottle holders

Type : Other, Automatic Rotary Bottle Washing Machine

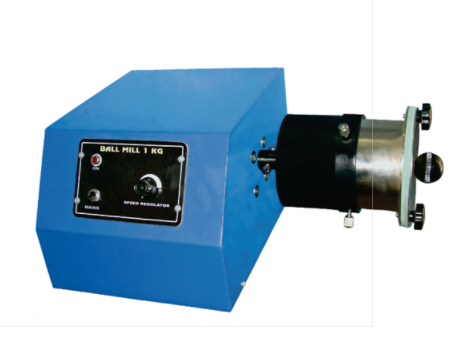

Ball Mill ( Laboratory Type)

Application : Grinding, mixing, and blending for laboratory use

Equipment Type : Laboratory Ball Mill

Equipment Materials : Mild Steel body with powder coated finish

Control Type : Digital Speed Controller

Features : Compact design, Easy operation, Low maintenance

Type : Other, Laboratory Type

Water Still Manasty Type

Application : Laboratory, Pharmaceutical, Chemical, Industrial

Equipment Type : Distillation Unit

Equipment Materials : Borosilicate glass condenser and heater housing, Stainless steel stand

Control Type : Manual (with safety cutoff)

Features : Automatic safety cutoff, easy to clean, energy efficient, wallmountable

Type : Other, Manasty Type

Level Measurement Trainer Module

Application : Educational training, Process Control, Laboratory experiments

Equipment Type : Trainer Module

Equipment Materials : Stainless Steel, Acrylic

Control Type : Manual and Automatic

Features : Corrosion Resistant, Transparent viewing, Calibration Scale, Portable

Type : Other, Level Measurement Trainer Module

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese