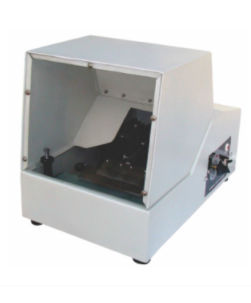

Rice Polisher Machine

Rice Polisher Machine Specification

- Control System

- PLC/Relay Control

- Installation Type

- Floor Mounted

- Material Grade

- MS Grade

- Processing Technology

- Advanced Polishing Roll

- Features

- Low maintenance, High efficiency, Robust construction

- Shape

- Rectangular

- Power Source

- Electric

- Application

- Rice Polishing

- Material

- Mild Steel

- Automatic Grade

- Automatic

- Capacity

- 2-8 Ton/hr

- Power

- 7.5 HP

- Voltage

- 220-440 V

- Temperature Range

- Ambient to 50C

- Usage

- Industrial

- Size

- Standard

- Dimension (L*W*H)

- 1850 x 650 x 1900 mm

- Weight

- 900 Kg

- Color

- White & Blue

- Belt Drive

- Yes

- Roller Material

- Abrasion Resistant Special Alloy

- Maintenance Access

- Front & Side Opening Panels

- Surface Finish

- Powder Coated

- Feeding Hopper

- Integrated

- Output Quality

- Uniform Shine Finish

- Dust Emission

- Minimized with Sealed Body Design

- Speed

- Variable (Adjustable as per requirements)

- Noise Level

- Low

- Dust Collector

- Attached Unit

- Spare Parts Availability

- Yes

About Rice Polisher Machine

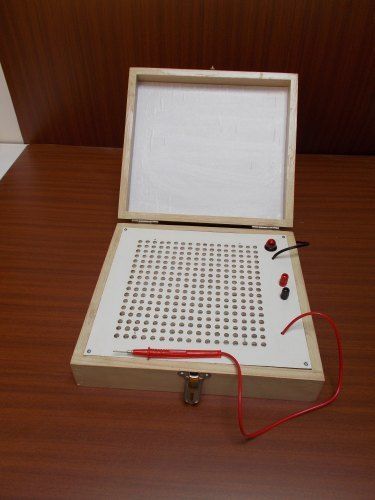

Rice Polisher Machine

| Brand | Micro Technologies |

| Voltage | 230 V |

| Frequency | 50 Hz |

| Sample Capacity | 800g Approx. |

| Power Required | 0.50 H.P. |

| Phase | Single Phase |

| Dimensions | 600x400x400 mm (LxBxH) |

Efficient Rice Polishing for Industrial Applications

This automatic rice polisher machine is engineered to meet the rigorous demands of rice mills and industrial processors. From its adjustable speed settings to its uniform output, it promises high throughput with reliable consistency. The stainless-steel rollers and powder-coated finish provide durability, while minimized noise and dust emissions help maintain safe, clean operations.

User-Friendly Features & Easy Maintenance

With an integrated feeding hopper and floor-mounted design, installing and operating the machine is simple. Maintenance is streamlined through front and side opening panels, offering direct access to internal components. Additionally, spare parts are readily available, ensuring minimized downtime for ongoing industrial usage.

FAQs of Rice Polisher Machine:

Q: How does the rice polisher machine achieve a uniform shine on rice grains?

A: The machine utilizes abrasion-resistant special alloy rollers and advanced polishing technology to ensure each rice grain is polished evenly. Adjustable speed controls let operators fine-tune the process for the best uniform shine, matching different rice varieties and processing requirements.Q: What is the process for maintaining the rice polisher machine?

A: Maintenance is straightforward due to front and side opening panels, which provide convenient access to internal parts. Routine tasks include cleaning, checking for wear, and replacing spare partsall of which are readily available from the manufacturer or distributor.Q: When should this machine be used in the rice processing workflow?

A: The rice polisher machine is typically used after rice has been milled and de-husked, serving as the final step to enhance the grains appearance and quality before packaging or export.Q: Where is the dust collected and how is dust emission minimized?

A: An attached dust collector captures particles generated during polishing. The machines sealed body design further minimizes dust emission, ensuring a safer and cleaner working environment.Q: What benefits does the advanced control system provide?

A: The integrated PLC or relay control system allows operators to precisely adjust speed and other settings, optimizing performance for various rice batches and ensuring consistent quality output with minimal manual intervention.Q: How does the integrated feeding hopper improve usage efficiency?

A: The built-in hopper streamlines continuous feeding of rice into the machine, reducing spillage and manual handling. This leads to smoother operation and consistent processing rates throughout the shift.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knife Sharpen Category

Automatic Razor Knife Sharpen

Color : Blue & Grey

Size : Standard

Power : Other, 2.2 kW

Capacity : Up to 60 pieces/hour

Dimension (L*W*H) : 1200 x 700 x 1100 mm

Application : Razor and knife sharpening in industrial and commercial settings

Commercial Cooker

Color : Silver

Size : Standard / Customizable

Power : Other, 2 kW 4 kW

Capacity : 60100 Liters

Dimension (L*W*H) : 650 mm x 650 mm x 950 mm

Application : Hotels, Restaurants, Commercial Kitchens

Atta Kneader Machine

Color : Silver

Size : Standard

Power : Other, 1 HP

Capacity : 10 kg/batch

Dimension (L*W*H) : 24 x 17 x 30 inch

Application : Flour Kneading for Roti, Chapati, Paratha

Human Maze Apparatus Pointed

Color : Yellow and Black

Size : Customizable

Power : Other, Not Required (Manual Operation)

Capacity : Single User

Dimension (L*W*H) : 320 cm x 200 cm x 150 cm (Approx.)

Application : Psychological and Behavioral Research

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese