At wood Machine

At wood Machine Specification

- Accuracy

- 0.05 mm

- Power Source

- Electric

- Features

- High Precision, Durable Structure, Low Maintenance, Energy Efficient

- Technology

- CNC (Computer Numerical Control)

- Machine Type

- AT Series Wood Machine

- Control System

- PLC Control System

- Operating Pressure

- 6-8 bar

- Surface Treatment

- Polished

- Accessories Type

- Router Bits, Tool Holders, Clamps

- Automation Grade

- Automatic

- Type

- Woodworking Machine

- Material

- Stainless Steel and Alloy

- Function

- Cutting, Shaping and Drilling Wood

- Application

- Furniture Manufacturing, Cabinetry, Wood Panel Processing

- Voltage

- 380V, 50Hz

- Table Structure

- Vacuum Table

- Spindle Speed

- 24000 rpm

- Software Compatibility

- Compatible with ArtCAM, Type3, Ucancam, JD Paint

- Spindle Power

- 6.0 kW

- Weight

- 1800 kg

- Drive Type

- Servo Motor Drive

- Max Working Area

- 1300 mm x 2500 mm

- Cooling System

- Water Cooling

About At wood Machine

At woodMachineConsisting of a full length brass upright graduated pipe up-to 200 cm, to be mounted vertically near a wall by means of two brackets. A light weight ac cu rate friction less wheel of 10 cm aid is mounted at its top: Three adjustable clamps move along the rod, upper carrying a ring and lower carrying a platform and the third on is equipped with electric release system. The unit is all metallic and complete with two set of falling weights and rider weight.

High-Precision Woodworking Technology

Engineered with CNC technology, the AT Series Wood Machine delivers reliable, high-precision results for various woodworking tasks. Its advanced servo motor drive and water cooling maintain performance without compromising on finish or material integrity. Ideal for professionals seeking consistent, repeatable production quality.

User-Friendly and Versatile Operation

The machine supports a wide range of design software, including ArtCAM and Type3, catering to diverse project needs. With PLC controls and automated features, users enjoy intuitive operation and minimal maintenance. The robust vacuum table and efficient power system enable seamless processing of even large or awkwardly shaped wood panels.

FAQ's of At wood Machine:

Q: How does the AT Series Wood Machine ensure high-precision woodworking?

A: The machine utilizes a servo motor drive system, delivering precise movements with an accuracy of 0.05 mm. Combined with the sturdy vacuum table and advanced PLC control system, this setup ensures that each cut, shape, or drilled hole is produced with exceptional consistency and minimal error.Q: What materials can the AT Series Wood Machine work with?

A: Designed primarily for woodworking applications, this machine efficiently cuts, shapes, and drills wooden panels. Its durable construction from stainless steel and alloy, along with powerful spindle and robust clamps, make it suitable for a variety of wood types and composite panels used in furniture and cabinetry manufacturing.Q: When is water cooling necessary during machine operation?

A: The water cooling system is essential for maintaining spindle temperature during extended high-speed operation-especially when running at 24,000 rpm. This feature prevents overheating, thereby prolonging spindle life and ensuring consistent machining performance.Q: Where can the AT Series Wood Machine be installed?

A: The machine is suitable for installation in industrial workshops, factories, and manufacturing facilities engaged in furniture making, cabinetry, or wood panel processing. It requires an electric power source of 380V, 50Hz and should be placed on a stable surface to support its 1800 kg weight.Q: What is the typical process workflow when using this machine?

A: Users first design parts in compatible software (such as ArtCAM or Ucancam), upload the file to the machine's control system, and secure the wooden workpiece on the vacuum table. The machine then automatically executes the programmed cutting, shaping, or drilling sequences according to the instructions.Q: How does the vacuum table function during operation?

A: The vacuum table holds wood securely in place by creating suction, which greatly reduces slippage and the need for manual clamping. This ensures consistent machining results, especially with large or thin workpieces, and facilitates quicker setup and changeover times.Q: What are the key benefits of using the AT Series Wood Machine in furniture manufacturing?

A: This CNC machine offers high precision, speed, and repeatability, enabling efficient mass production of furniture components. Its durable design ensures a long service life, while automation reduces labor costs and human error, resulting in enhanced productivity and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Geared Jib Crane

Features : 360degree rotation, robust base plate, ease of installation, low maintenance

Type : Jib Crane

Machine Type : Manual/Geared Jib Crane

Technology : Geared mechanism for smooth rotation and precise load handling

Accuracy : High positioning accuracy due to geared rotation

Power Source : Manual power

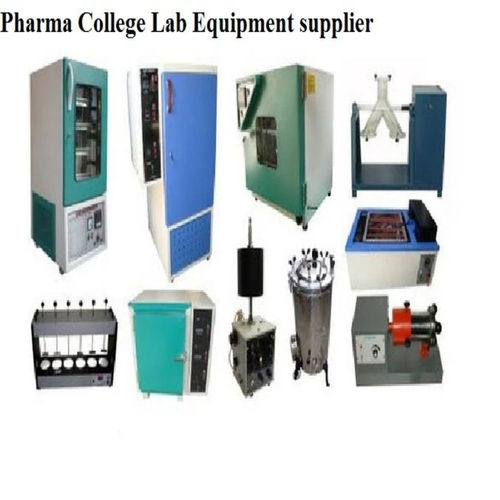

Pharmacy Lab Equipment

Features : Corrosion Resistant, Easy to Clean, Durable

Type : Pharmacy Lab Equipment

Machine Type : Manual and SemiAutomatic

Technology : Advanced Laboratory Instrumentation

Accuracy : High Precision (0.01%)

Power Source : Electric

Young Modulus of A Metal Rod by an indifference Method

Features : High Precision, Durable Construction, Easy to Operate

Type : Laboratory Experiment Apparatus

Machine Type : Measurement Apparatus

Technology : Indifference Method

Accuracy : Up to 0.01 mm

Power Source : Manual Operation

Parallel Forces Apparatus

Features : Rugged construction, corrosionresistant, easy to use, complete with accessories

Type : Parallel Forces Apparatus

Machine Type : Educational Equipment

Technology : Mechanical

Accuracy : 1 mm

Power Source : Manual

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese