Compound Lever

Compound Lever Specification

- Machine Type

- Manual or Semi-Automatic Press

- Operating Pressure

- Depends on Machine Capacity

- Features

- Robust Construction, High Load Capacity, Durable Finish

- Control System

- Mechanical

- Surface Treatment

- Polished / Anti-Corrosive Coating

- Technology

- Compound Lever Mechanism

- Accuracy

- High Force Transfer Precision

- Automation Grade

- Manual

- Accessories Type

- Lever Assembly

- Power Source

- Manual Operation

- Type

- Mechanical Lever

- Material

- High-Grade Steel

- Function

- Transfers Force with Mechanical Advantage

- Application

- Industrial machinery, Press Machines

- Voltage

- N/A (mechanical operation)

- Load Capacity

- Up to 10 Tons (varies by model)

- Mounting

- Bolted or Welded

- Packaging Type

- Carton/Box Packaging

- Weight

- Depends on Size and Model

- Size/Dimensions

- Standard and Custom Sizes Available

- Finish

- Rust-Resistant Finish

- Service Life

- Long Service Life

About Compound Lever

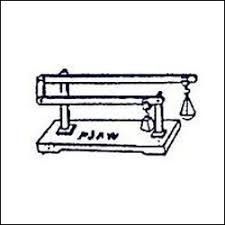

Compound LeverComprisingof two iron beams connected to each other and fitted on two different stands,well balanced with a scale pan. All metal parts fitted on wooden polished base.Complete with 1kg. Weight and a physical iron nickelled weight box 1-50 gms

Engineered for Strength and Precision

Our compound levers are meticulously manufactured using advanced compound lever mechanisms and high-grade steel. They ensure maximum mechanical advantage, supporting heavy-duty industrial use with uncompromising accuracy and robust construction. Precision in force transfer means less wear and consistent performance even in demanding operations.

Flexible Sizing and Customization

Choose from standard sizes or get compound levers tailored to your exact specifications. Whether your machinery requires a particular dimension or load capacity, our team provides custom solutions that align with your needs, ensuring optimal compatibility and outstanding operational efficiency.

Long-Lasting Rust-Resistant Finish

Each lever is treated with a specially formulated anti-corrosive coating and polished for an attractive, enduring finish. This not only prolongs the service life but also minimizes maintenance, making our levers a reliable investment for harsh industrial environments.

FAQ's of Compound Lever:

Q: How is the compound lever installed on industrial machines?

A: The compound lever can be mounted securely using either bolted or welded methods. This flexibility allows it to integrate seamlessly with various types of industrial press machines or manual press equipment as per your installation requirements.Q: What types of applications are suited for this compound lever?

A: This mechanical lever is ideal for use in industrial machinery, particularly manual or semi-automatic press machines, where high force transfer precision and durability are paramount. Its strong construction and load capacity up to 10 tons support a wide array of force-intensive tasks.Q: When should I opt for a custom-size compound lever?

A: Custom sizes are recommended when your machinery has unique dimensional requirements or specific load capacities that standard models cannot accommodate. Our manufacturing team can design a lever tailored to fit your operational needs and machinery configurations.Q: Where is the compound lever typically used in India?

A: These levers are widely utilized by distributors, exporters, manufacturers, suppliers, and traders throughout India, especially in sectors involving heavy machinery, metalworking, and fabrication industries that demand high mechanical advantage and precision.Q: What benefits does the rust-resistant finish provide?

A: The rust-resistant, polished, and anti-corrosive surface treatment ensures the lever remains durable even in harsh environments. It reduces the risk of corrosion, cutting down on maintenance costs and extending service life.Q: How does the compound lever enhance force transfer in machines?

A: Utilizing a compound lever mechanism, the device multiplies input force, enabling users to exert significant force with reduced effort. This mechanical advantage leads to precise, consistent, and efficient operation of press machines and other industrial equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

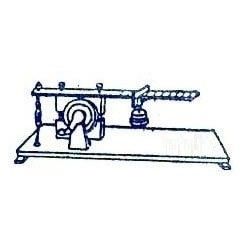

Crony Brake Dynamometer

Technology : Mechanical/Electromechanical

Type : Absorption Type Dynamometer

Accuracy : 0.5% of Full Scale

Automation Grade : SemiAutomatic / Manual

Accessories Type : Connecting Shafts, Couplings, Display Panel

Function : Measures Brake Force, Torque, and Power Output

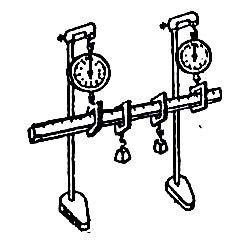

Parallel Forces Apparatus Overhang Beam Type

Technology : Mechanical

Type : Overhang Beam Type

Accuracy : High accuracy with precise graduated scale

Automation Grade : Manual

Accessories Type : Weights set, hangers, pointer, graduated scale

Function : Demonstrates the principle of parallel forces and moments

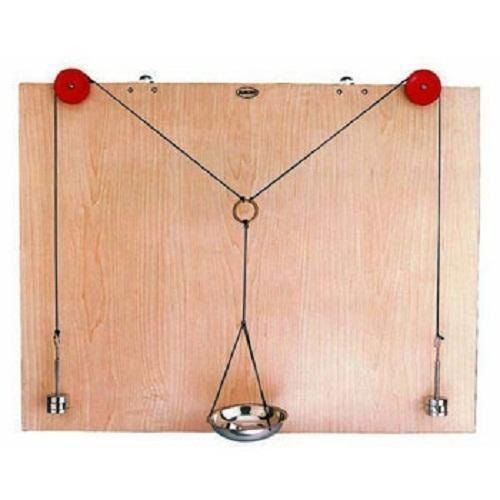

Polygon & Triangle of Forces Apparatus

Technology : Mechanical

Type : Educational Physics Laboratory Apparatus

Accuracy : High

Automation Grade : Manual

Accessories Type : Weights, Hooks, Pulleys, Protractor, Nylon String

Function : To verify and study the equilibrium of concurrent coplanar forces using the law of polygon and triangle of forces

Simple Pendulum

Technology : Mechanical Demonstration

Type : Physics Laboratory Equipment

Accuracy : High precision for educational purposes

Automation Grade : Manual

Accessories Type : Brass Bob, Rigid Stand, Suspension String

Function : To demonstrate laws of simple harmonic motion and measure acceleration due to gravity (g).

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese