Crony Brake Dynamometer

Crony Brake Dynamometer Specification

- Surface Treatment

- Paint Coated & Anti-Corrosive Finish

- Accessories Type

- Connecting Shafts, Couplings, Display Panel

- Operating Pressure

- Hydraulic Oil: 30-120 Bar

- Control System

- Analog Meter & Digital Indicator (Optional)

- Machine Type

- Brake Dynamometer

- Power Source

- Electric (AC Powered)

- Automation Grade

- Semi-Automatic / Manual

- Technology

- Mechanical/Electromechanical

- Accuracy

- 0.5% of Full Scale

- Features

- Heavy Duty Construction, High Precision Sensors, Overload Protection, Easy Calibration

- Type

- Absorption Type Dynamometer

- Material

- High-grade Alloy Steel, Cast Iron

- Function

- Measures Brake Force, Torque, and Power Output

- Application

- Automotive, Engineering Institutes, Research & Development

- Voltage

- 230 V / 415 V AC, 50 Hz

- Standards Compliance

- As per IS/ISO Automotive Testing Standards

- Cooling System

- Water Cooled

- Capacity

- 5 HP to 300 HP Varients Available

- Speed Range

- Up to 3500 RPM

- Display Type

- Bright Analog Dial &/or Digital Display

- Torque Range

- Up to 1000 Nm (Customizable)

- Safety Features

- Emergency Stop Switch, Enclosed Protective Covers

- Data Output

- Optional USB/Serial Data Interface for Computer Logging

- Weight

- Approx. 250-800 kg depending on model

- Mounting Type

- Base Plate Mounted with Vibration Absorbers

- Ambient Temperature Range

- 5°C to 55°C

- Calibration

- Factory Calibrated, Calibration Certificate Included

About Crony Brake Dynamometer

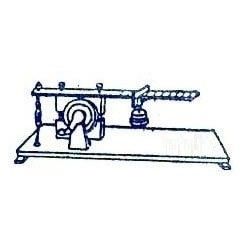

Crony Brake DynamometerConsistingof two blocks of wood clamped together with a pulley in the center. The pulleyis fitted to a halt moving on the ball bearings. A lever bar is attached to one of the blocks carrying aweight hanger at the outer and spring balance is also fitted to measure theload factor developed with the lightening of the block with wing nuts andspring.

Versatile Torque and Speed Range

Designed to measure torque up to 1000 Nm and speeds up to 3500 RPM, the Crony Brake Dynamometer caters to a broad spectrum of testing needs, while customizable options ensure optimal alignment with diverse requirements in automotive engineering and research environments.

Enhanced Safety and Durability

Safety features such as enclosed protective covers, emergency stop switch, and vibration-absorbing base plate mounting provide reliable operation. Built from high-grade alloy steel and cast iron, the dynamometer delivers robust performance even in demanding conditions.

Comprehensive Data and Control Options

Operators can choose between bright analog dials or digital displays, and optionally benefit from USB/serial data output for computer-based logging. The system supports semi-automatic or manual operation, allowing flexibility in measurement and process control.

FAQ's of Crony Brake Dynamometer:

Q: How is the Crony Brake Dynamometer calibrated and certified?

A: Each unit is factory calibrated for precision and comes with a calibration certificate, ensuring consistent accuracy of 0.5% of full scale and compliance with IS/ISO automotive testing standards.Q: What variants of power capacity are available for this dynamometer?

A: The Crony Brake Dynamometer offers models ranging from 5 HP up to 300 HP, allowing users to select the most suitable variant for their testing and application requirements.Q: Where can the Crony Brake Dynamometer be used?

A: This dynamometer is ideal for use in automotive testing, research and development, engineering institutions, and laboratories involved in brake force and power measurement.Q: Which safety features are integrated in the Crony Brake Dynamometer?

A: Key safety components include an emergency stop switch, enclosed protective covers, and robust base plate mounting with vibration absorbers to ensure operator protection and equipment stability.Q: What process is involved in logging and displaying test data?

A: Operators can view results via bright analog or digital displays. For advanced analysis, an optional USB/serial data interface enables direct computer logging and further data evaluation.Q: What are the main benefits of using this brake dynamometer?

A: The main advantages include high measurement precision, durable construction, overload protection, flexible control options, and robust safety measures, resulting in reliable operation in professional testing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Sediment Transport Demonstration Channel

Type : Sediment Transport Demonstration Channel

Surface Treatment : Powder Coated Finish

Accessories Type : Sediment feeder, filter screens, flow meters

Automation Grade : Manual and SemiAutomatic

Application : Laboratory for Civil Engineering, Hydraulic Engineering Education, Research Institutes

Technology : Hydraulic Engineering Demonstration

Pharmacy Lab Equipment

Type : Pharmacy Lab Equipment

Surface Treatment : Polished Finish

Accessories Type : Standard Lab Accessories Included

Automation Grade : SemiAutomatic

Application : Pharmacy Colleges, Pharmaceutical Labs

Technology : Advanced Laboratory Instrumentation

Structural mechanics apparatus

Type : Educational Training Equipment

Surface Treatment : Powder Coated

Accessories Type : Weights, Loading Pins, Measuring Scales

Automation Grade : Manual

Application : Laboratory, Research, Academic Institutes

Technology : Mechanical

Friction Slide

Type : Friction Slide

Surface Treatment : Polished/Zinc Plated

Accessories Type : Mounting Screws/Brackets

Automation Grade : Manual

Application : Drawers, Cabinets, Sliding Systems

Technology : Modern Sliding Mechanism

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese