Structural mechanics apparatus

Structural mechanics apparatus Specification

- Features

- Robust Construction, Corrosion Resistant, Portable, Easy-to-Use

- Technology

- Mechanical

- Machine Type

- Bench Top Apparatus

- Accessories Type

- Weights, Loading Pins, Measuring Scales

- Accuracy

- High Accuracy (0.01 mm Deflection)

- Operating Pressure

- Atmospheric

- Surface Treatment

- Powder Coated

- Power Source

- Not Electric, Operated Manually

- Automation Grade

- Manual

- Control System

- Mechanical Controls

- Type

- Educational Training Equipment

- Material

- Mild Steel and Aluminum

- Function

- Demonstrates Structural Mechanics Principles

- Application

- Laboratory, Research, Academic Institutes

- Voltage

- Not Required (Manual Apparatus)

- Assembly

- Supplied Knock-Down for Easy Assembly

- Instruction Manual

- Comprehensive Guide Provided

- Dimensions

- Approx. 800 mm x 300 mm x 400 mm

- Measuring Devices

- Dial Gauge, Graduated Scales

- Experimental Modules Included

- Simply Supported Beam, Cantilever, Truss Members

- Max Load Capacity

- Up to 10 kg depending on configuration

- Standards Compliance

- Designed as per Educational Curriculum & Laboratory Norms

- Frame Structure

- Rigid Steel Base with Removable Components

- Weight

- Approx. 18 kg

- Finish

- Epoxy Powder Coated

About Structural mechanics apparatus

1. (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14) North Light Roof Truss.

Details of Accessories :-

(a) Stand and cross bars(4 bars & 8 stands) 4 Sets.

(b) Brackets fitted withstands. 4 only.

(c) Hinges(different) 22 only.

(d) Hinge HolderHooks. 8 only.

(e) Cantilever rod withtop caps. 2 only.

(f) Member rods (sizesmarked) 37 only.

(g) Cap Screws(extra). 6 only.

(h) Weight hanger withplatform. 8 only.

(i) Weight platformsextra. 2 only.

(j) Slotted weights1kg. 10only.

(k) Spring balances (2 of20kg. 2 of 10kg. 4 of 5kg. 8 only.

(l) Chains short andlong. 6 only.

(m) Boss Brackets. 2 only.

(n) Ring Brackets. 5 only.

(o) Hook brackets. 4 only.

(p) Pulley brackets. 3 only.

(q) Member balances toindicate tensile force 3only.

(r) Member balances toindicate compressive force. 3 only.

All parts are interchangeable so that thedifferent frame works can be assembled with same components. All the components(except cross bars and stands) are supplied in a polished wooden box. Completewith assemblies drawings leaflet.

Engineered for Effective Learning

This apparatus is specifically designed to meet educational curriculum requirements in structural mechanics. Its modular setup allows students and researchers to carry out several classic experiments easily, deepening their understanding of structural behavior under various loading conditions.

Reliable Build and Portability

Manufactured with high-quality mild steel and aluminum, the powder-coated finish ensures durability and resistance against corrosion. The unit's knock-down assembly and portable size make it suitable for various laboratory spaces and straightforward for educators to set up and relocate as needed.

Manual Operation for Hands-On Experience

No power source is required, as the entire apparatus is mechanically operated. This approach nurtures practical skills by encouraging users to physically engage with the equipment, manipulate loads, and observe resultant structural responses using provided measurement devices.

FAQ's of Structural mechanics apparatus:

Q: How is the structural mechanics apparatus assembled and set up for use?

A: The apparatus is supplied as a knock-down kit, allowing for easy on-site assembly. A comprehensive instruction manual guides users through each assembly step, ensuring that the frame, experimental modules, and measuring devices are securely and accurately set up for immediate use in the laboratory.Q: What types of experiments can be performed with this equipment?

A: This apparatus allows demonstration and analysis of various structural concepts, including simply supported beams, cantilever arrangements, and truss member behavior. Users can measure deflections and reactions under different load applications, providing practical insights into real-world structural engineering problems.Q: When is this apparatus most beneficial in an educational context?

A: It is most useful during structural mechanics courses or laboratory sessions in academic institutes, where hands-on experimentation and measurement of structural behavior are integral to the curriculum. Its high accuracy and easy usability make it ideal for both demonstrations and student-led investigations.Q: Where is this apparatus typically used?

A: The structural mechanics apparatus is commonly used in laboratories, research facilities, and academic institutions focusing on civil or mechanical engineering. Its bench-top design makes it especially suitable for settings where space efficiency and portability are important.Q: What are the main benefits of using this apparatus for structural mechanics training?

A: The apparatus delivers high measurement accuracy (0.01 mm), robust and corrosion-resistant construction, and flexible modularity for a range of experiments. Its manual operation nurtures hands-on skills while illustrating key mechanics principles, all in compliance with educational standards.Q: How are measurements taken with this equipment?

A: The system is equipped with a dial gauge and graduated scales for precise measurement of structural deflections and responses. Users apply loads manually using weights and loading pins, and observe the resulting deformations directly on the measuring devices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

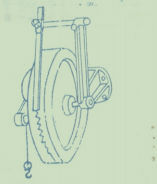

Ropo Brake and Dynamometer

Surface Treatment : Powder Coated and Galvanized

Operating Pressure : Up to 7 Bar

Function : Measures and tests braking force and performance

Automation Grade : Automatic

Power Source : Electric

Application : Automobile, Industrial Machinery, Laboratory Testing

Screw Jack

Surface Treatment : Paint Coated

Operating Pressure : Ambient/Mechanical (Not Pneumatic)

Function : Lifting/Lowering Loads

Automation Grade : Manual

Power Source : Manual

Application : Automotive, Construction, Industrial Maintenance

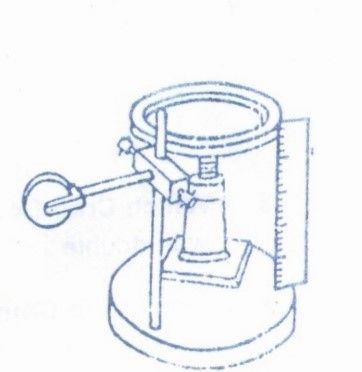

D Pharmacy Instrument

Surface Treatment : Polished

Operating Pressure : Ambient

Function : Pharmaceutical Analysis

Automation Grade : Manual

Power Source : None (Manual Operation)

Application : D Pharmacy Practical Demonstrations

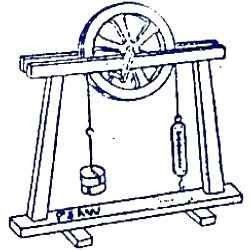

Moment of Inertia of Flywheel

Surface Treatment : Paint Coated

Operating Pressure : Atmospheric/Not applicable

Function : To determine the moment of inertia of the flywheel

Automation Grade : Manual

Power Source : Gravity/Manual

Application : Physics Laboratory/Engineering Laboratory

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese