Ropo Brake and Dynamometer

Ropo Brake and Dynamometer Specification

- Accessories Type

- Load Cell, Sensors, Digital Interface, Cables

- Control System

- Digital Display with PLC Control

- Power Source

- Electric

- Automation Grade

- Automatic

- Technology

- Electromagnetic Brake System

- Accuracy

- 0.5%

- Features

- High Precision, User Friendly, Low Maintenance, Durable

- Operating Pressure

- Up to 7 Bar

- Machine Type

- Testing and Measuring Equipment

- Surface Treatment

- Powder Coated and Galvanized

- Type

- Ropo Brake Dynamometer

- Material

- High Grade Steel and Cast Iron

- Function

- Measures and tests braking force and performance

- Application

- Automobile, Industrial Machinery, Laboratory Testing

- Voltage

- 220-240 V

- Ambient Temperature Range

- 0°C to 50°C

- Display Type

- Digital LCD Display

- Mounting Type

- Floor Mounted

- Signal Output

- Analog & Digital Output options

- Cooling System

- Air and Water Cooled

- Test Speed Range

- 10-3000 RPM

- Frequency

- 50/60 Hz

- Maximum Torque Capacity

- 500 Nm

About Ropo Brake and Dynamometer

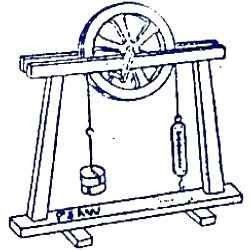

Ropo Brake and Dynamometer

Consists ofa cast iron truly machine need wheel of 45 cm dia with a groove the steel axleis mounted on call bearings to minimizefriction and assembled on a sturdy wooden frame Provided with an extensionbalance, rope and a set of slotted weights and hanger.

Advanced Electromagnetic Braking Technology

The Ropo Brake Dynamometer utilizes an electromagnetic brake system that delivers reliable and consistent performance. The technology provides rapid response times and ensures precise control of braking force, making it suitable for sensitive measurement and testing applications. Its digital interface and PLC-based control system enhance test automation, accuracy, and repeatability.

Versatile Cooling and Precision Engineering

Designed with both air and water cooling systems, this dynamometer maintains optimal operating temperatures even under heavy loads. The use of high grade materials and robust surface treatments-powder coating and galvanization-guarantee long service life. Its versatility extends to a wide test speed range, supporting multiple applications in automotive testing, industrial machinery, and laboratory environments.

User-Friendly Operation and Comprehensive Accessories

Featuring an easy-to-read digital LCD display and fully automatic PLC controls, the Ropo Brake Dynamometer streamlines the testing process. It comes equipped with all essential accessories like load cells, sensors, cables, and digital interfaces, ensuring users achieve high-precision results with minimal effort or maintenance.

FAQ's of Ropo Brake and Dynamometer:

Q: How does the Ropo Brake Dynamometer achieve high measurement accuracy?

A: The dynamometer employs a sophisticated electromagnetic brake system, advanced digital PLC control, and high-precision load cells, resulting in an accuracy of 0.5%. Air and water cooling ensure thermal stability, maintaining consistent performance through all test cycles.Q: What is the process for using the Ropo Brake Dynamometer in laboratory testing?

A: Set up the dynamometer securely on the floor, connect the material to be tested, and select the desired test parameters via the digital LCD interface. The automated system manages control variables, cooling, and measurement, while outputs can be captured via analog or digital interfaces for analysis.Q: When should I opt for air cooling or water cooling with this dynamometer?

A: Air cooling is sufficient for standard or short-duration tests at moderate torque and speed. Water cooling is recommended during prolonged, high-load operations or when maximum heat dissipation is required to maintain test accuracy and protect equipment longevity.Q: Where can the Ropo Brake Dynamometer be used?

A: This equipment is suitable for automobile test centers, industrial machinery manufacturing units, laboratory research settings, and any application needing high-precision force and performance measurements.Q: What are the primary benefits of using this dynamometer system?

A: Key benefits include its high precision, wide operational range (10-3000 RPM), robust construction for durability, low maintenance requirements, and user-friendly automated controls. These features ensure reliable, repeatable measurements in diverse testing environments.Q: How is data output managed and integrated into other systems?

A: The dynamometer supports both analog and digital output signals, enabling easy integration with data acquisition systems, computers, or laboratory information management systems for comprehensive analysis and reporting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Shear Legs Apparatus

Material : Mild Steel (MS)

Technology : Mechanical

Automation Grade : Manual

Power Source : Manual

Control System : Manual Operation

Accessories Type : Pulley Block, Rope, Weights

Law of Conservation of Mass (Collision in 2-D Apparatus)

Material : Highgrade Aluminum & Steel

Technology : Impact and Momentum Demonstration

Automation Grade : Manual

Power Source : Manual

Control System : Mechanical

Accessories Type : Collision Balls, Platform, Rulers

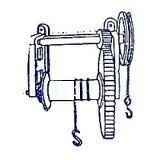

Winch Crab Single Purchase

Material : Mild Steel

Technology : Single Purchase Mechanism

Automation Grade : Manual

Power Source : Manual/Hand Operated

Control System : Hand Operated

Accessories Type : Wire Rope, Hook

Shear Force Apparatus

Material : Mild Steel Frame, Stainless Steel Components

Technology : Mechanical Measurement

Automation Grade : Manual

Power Source : Manual Operation

Control System : Hand Operated Mechanism

Accessories Type : Dial Gauge, Weight Set, Instruction Manual

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese