Compression of Coiled Springs

Compression of Coiled Springs Specification

- Technology

- Compression of Coiled Springs

- Power Source

- Electric

- Accuracy

- 0.01 mm

- Automation Grade

- Semi-automatic

- Machine Type

- Spring Compression Testing Machine

- Features

- High Durability, Corrosion Resistant, Precision Engineered

- Surface Treatment

- Polished

- Control System

- Digital Display

- Accessories Type

- Compression Plates, Digital Gauge

- Operating Pressure

- Up to 1000 N

- Type

- Coiled Compression Spring

- Material

- Stainless Steel

- Function

- Absorbs shock and returns to original position after compression

- Application

- Automotive, Industrial Machinery, Electronics

- Voltage

- 220 V

- Spring Diameter Range

- 0.2 mm to 65 mm

- Color

- Customizable (Standard: Green/Grey/Blue)

- Finish Type

- Smooth Finish

- Display Type

- Digital / Analog

- Test Capacity

- Up to 50 Ton

- Operating Temperature

- -20°C to 200°C

- Free Length Range

- 5 mm to 800 mm

- Load Cell Type

- Strain Gauge Load Cell

- Installation

- Onsite Support Available

About Compression of Coiled Springs

Compression of Coiled Springs: Application & Usage

Compression of coiled springs is essential for a broad spectrum of applications. Majorly used in automotive production, industrial machinery, and electronic equipment, these springs absorb shocks and consistently return to their original positions post-compression. Preferred by engineers, manufacturers, and quality control experts, the device efficiently tests and validates spring performance. Its precision and reliability make it invaluable for machinery builders and production lines requiring robust and accurate spring operation.

Superior Supply, Swift Transportation and Global Markets

We take pride in our unparalleled supply ability, capable of dispatching bulk orders promptly from our FOB port in India. Harnessing efficient transportation networks, we offer seamless delivery for domestic and international clients. Our main export markets include Asia, Africa, the Middle East, and Europe. Every order receives meticulous attentionfrom packaging to transportationso clients receive their equipment efficiently and in flawless condition, enabling prompt installation and immediate usage.

FAQs of Compression of Coiled Springs:

Q: How does the digital display improve the accuracy of spring compression testing?

A: The digital display provides real-time, precise measurements with an accuracy of 0.01 mm, ensuring that each test result is reliable and easy to interpret for quality control and analysis.Q: What industries benefit most from using this spring compression testing machine?

A: Automotive, industrial machinery, and electronics sectors gain significant advantages, as this machine assures that springs used in their products meet stringent performance and safety requirements.Q: Where can the coiled compression springs be installed and who offers support?

A: The springs can be installed in various machinery and equipment with onsite support available across India, provided by skilled technicians to ensure seamless setup and integration.Q: What is the process for ordering and receiving these compression springs for international clients?

A: Clients can place orders directly with us; products are dispatched via trusted transportation networks from our FOB port, with careful packaging and prompt communication for efficient international shipping.Q: How does the strain gauge load cell enhance the machines functionality?

A: The strain gauge load cell accurately measures compressive forces up to 50 tons, enabling detailed analysis and repeatability for a wide range of spring sizes and loads.Q: What surface treatments and finish options are available for customization?

A: The springs feature a smooth, polished finish and are available in customizable colors such as green, grey, or blue to match your specific preferences or branding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Pharmacy Lab Equipment

Machine Type : Manual and SemiAutomatic

Application : Pharmacy Colleges, Pharmaceutical Labs

Function : Analysis and Testing of Pharmaceutical Samples

Features : Corrosion Resistant, Easy to Clean, Durable

Surface Treatment : Polished Finish

Control System : Digital and Analog Controls

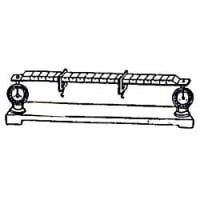

Parallel Forces Apparatus

Machine Type : Benchmounted experimental unit

Application : Physics laboratory, Engineering education, Science demonstration

Function : To demonstrate equilibrium of parallel forces in mechanics experiments

Features : Sturdy construction, Portable, Easy assembly/disassembly, Precise measurement scale

Surface Treatment : Powder coated and polished anticorrosive finish

Control System : Handoperated mechanical controls

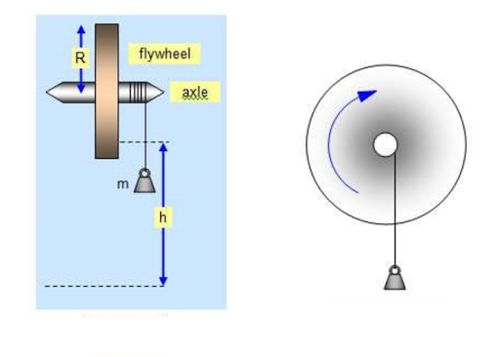

Moment of Inertia of Flywheel

Machine Type : Flywheel Setup

Application : Physics Laboratory, Engineering Institution

Function : Determine Moment of Inertia

Features : Sturdy design, Durable, Precise measurement

Surface Treatment : Polished

Control System : Mechanical

Friction Slide

Machine Type : Furniture & Industrial Fittings

Application : Drawers, Cabinets, Sliding Systems

Function : Enable Smooth Linear Movement

Features : Durable, Corrosion Resistant, Easy Installation

Surface Treatment : Polished/Zinc Plated

Control System : Manual Operation

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese