Elevator Lift Control Module

Elevator Lift Control Module Specification

- Automation Grade

- Automatic

- Mounting Type

- DIN Rail or Panel Mount

- Application

- Elevator Control/Automation

- Accuracy

- High Operational Precision

- Resolution

- Digital/Addressable Inputs

- Temperature

- -10C to +60C

- Display Type

- LED Indicator

- Response Time

- <20 ms

- Operating Voltage

- DC 12V/24V

- Power Supply

- DC 12V/24V

- Max Height

- Supports High-Rise Applications

- Interface Type

- Relay Output, Digital Input

- Humidity

- 0-95% RH, Non-condensing

- Port Size

- Standard Input/Output Terminals

- Frequency

- 50/60 Hz

- Equipment Type

- Elevator Lift Control Module

- Features

- Short Circuit Protection, Overload Protection, Programmable Logic, Automatic/Manual Mode

- Hardness

- Industrial Grade Electronic PCB

- Usage

- Lift and Elevator Circuit Control

- Capacity

- Supports Up to 24 Floors

- Machine Weight

- 350 g

- Control Mode

- Microprocessor-Based

- Material

- High-Grade PCB with Flame Retardant Casing

- Firmware

- Upgradeable via Serial Port

- Indicator Lights

- LED for Power, Fault & Operation

- Input Channels

- 24 Digital Inputs

- Compatibility

- Suitable for Most Elevator Types

- Dimensions

- 160 mm x 110 mm x 30 mm

- Communication Protocol

- RS485/Serial Communication, Optional Ethernet

- Output Channels

- 16 Relay Outputs

- Protection Class

- IP20

About Elevator Lift Control Module

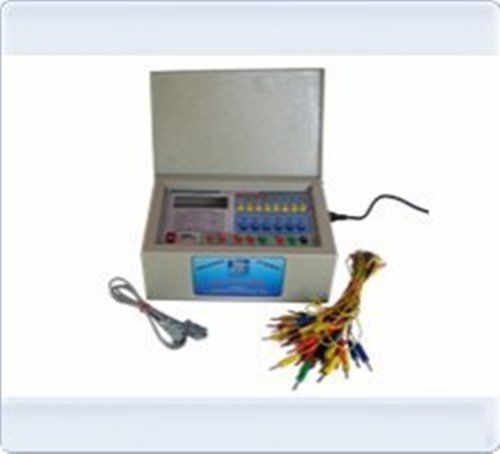

Elevator Lift Control Module

| Brand | Micro Technologies |

| Inputs | Lift up, Lift down, 4 lift position LEDs 8 acknowledgement LEDs, buzzer for error indication. |

| Outputs | 4 proximity sensors, 4 lift calling push buttons Door open / close toggle switch, buzzer, lift up li |

| Logic Level | 24V DC |

| Connection | via 4mm patch card terminals or d type sub-plugs for quick connection to PLC base plate. |

| Measurements | 650x340x400(HxBxD,mm)approx. |

Advanced Elevator Automation

This control module delivers smart automation for diverse elevator systems, utilizing programmable logic to manage lift operations efficiently. Its microprocessor-based design ensures reliable control with digital precision, supporting modern elevator circuit requirements in automatic or manual mode.

Robust Safety and Protection

With built-in flame retardant casing, short circuit, and overload protection, the module guarantees safe operation in demanding conditions. The indicator LEDs promptly inform users of power status, faults, and ongoing activity, facilitating proactive maintenance and system monitoring.

Flexible Integration and Upgradability

Supporting RS485/Serial and optional Ethernet communication, the unit easily interfaces with contemporary building infrastructure. DIN rail or panel mounting options simplify installation, while upgradeable firmware via the serial port ensures future-proof adaptability.

FAQ's of Elevator Lift Control Module:

Q: How does the Elevator Lift Control Module interface with building management systems?

A: The module communicates using RS485 or serial protocols, with optional Ethernet available, allowing seamless integration with building automation and elevator management systems for efficient monitoring and control.Q: What is the installation process for this lift control module?

A: Installation is straightforward; the device mounts on a DIN rail or panel. Standard input/output terminals make wiring simple, and the module operates on DC 12V or 24V, fitting standard elevator electrical configurations.Q: Where can this control module be used?

A: This module suits most elevator types, including residential, commercial, and high-rise applications. Its robust industrial-grade construction and IP20 protection class make it ideal for deployment in diverse indoor environments across India.Q: What benefits does the upgradeable firmware offer?

A: Upgradeable firmware via the serial port ensures the module can adapt to future protocol changes or feature enhancements, protecting the user's investment and minimizing system downtime during updates.Q: How does the module enhance elevator safety and reliability?

A: Safety is assured with flame retardant casing, short circuit, and overload protection, as well as real-time LED indicators for operational status and faults. These features help prevent hazards and support rapid issue resolution.Q: What are the module's usage capabilities?

A: It controls lift and elevator circuits automatically or manually, supporting up to 24 floors and enabling accurate, responsive, and addressable operations for complex elevator systems.Q: When should the firmware be upgraded?

A: Firmware should be upgraded when new features, performance improvements, or security patches are available from the manufacturer or supplier. It is easily performed via the serial communication port as part of routine maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing And Measuring Equipments Category

Analgesio meter

Control Mode : Microprocessor based digital

Power Supply : 220 V AC, 50 Hz

Machine Weight : 10 kg

Capacity : Digital display up to 1000 g

Humidity : 80% RH

Accuracy : 1% of reading

ISI Interlocking Lab

Control Mode : Digital Touch Screen Control

Power Supply : 220V, 50 Hz, Single Phase

Machine Weight : Approx. 250 kg

Capacity : 50 kN

Humidity : 30%80% RH

Accuracy : 1%

L.D.R Trainer

Control Mode : Manual

Power Supply : 230V AC, 50 Hz

Machine Weight : 8 Kg

Capacity : 5 Litres

Humidity : 40% 80% RH

Accuracy : 0.1 mm

PLC Trainer UI PLC 6DA

Control Mode : Manual & Automatic

Power Supply : 230 V AC, 50 Hz

Machine Weight : 12 kg

Capacity : For training up to 6 I/O examples

Humidity : 40% 85% RH

Accuracy : High Precision

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese