RICE ANALYZER

RICE ANALYZER Specification

- Shape

- Rectangular

- Features

- Automated sample feed, LCD display, data storage

- Usage & Applications

- Quality control, research, rice mills, labs

- Tool Type

- Laboratory Equipment

- Noise Level

- Low

- Product Type

- Rice Analyzer

- General Use

- Accurate analysis & quality assessment of rice grains

- Capacity

- 500-1000 g samples

- Weight (kg)

- 18

- Type

- Digital Grain Analyzer

- Drive Type

- Electric

- Power

- 220V AC, 50Hz

- Power Source

- Electricity

- Start Method

- Automatic

- Machine Speed

- Rapid assessment (within seconds)

- Material

- ABS Plastic, Metal

- Dimension (L*W*H)

- 405mm x 310mm x 190mm

- Color

- Gray/White

- Display Type

- Digital LCD Display

- Safety Features

- Overload Protection, Error Alarms

- Calibration

- Auto-calibration function

- Data Storage

- Internal memory with export capability

- Operating Temperature

- 5°C to 40°C

- Connectivity

- USB and RS232 ports

- Packaging Type

- Carton Box with Foam Inserts

- Software

- Windows compatible analysis software included

- Power Consumption

- Max. 40W

- Sample Tray Material

- Stainless Steel

- Counting Method

- Image Sensor Based Counting and Sorting

- Analysis Parameters

- Length, Thickness, Broken Percentage, Whiteness, Chalkiness

About RICE ANALYZER

RICE ANALYZER

| Parameters | It calculates the length breadth Ratio, and area of individual indexed rice grain. |

| Classification | Rice can be classified according to user-specified parameters in categories like |

| Data Logging | Classification parameters of Rice grain can be stored in a database index with rice grain names. |

Advanced Digital Display & Image Analysis

The RICE ANALYZER features a bright digital LCD display for easy monitoring and user interaction. Its high-precision image sensor-based system enables accurate counting and sorting of rice grains, delivering analysis on key parameters like grain length, thickness, broken percentage, whiteness, and chalkiness. This cutting-edge technology ensures that every sample is evaluated with consistent accuracy and speed, supporting efficient quality control.

Robust Build and User-Friendly Operation

Designed for durability and ease of use, the RICE ANALYZER boasts a stainless steel sample tray housed within an ABS plastic and metal body, ensuring long-term reliability. The machine operates at low noise levels and consumes only up to 40W of power. Its automated sample feed and intuitive interface make it suitable for users in labs, rice mills, research institutions, and commercial settings.

Seamless Data Handling and Connectivity

Equipped with internal memory and export capability, the RICE ANALYZER allows users to store, manage, and transfer data effortlessly. Connectivity options through USB and RS232 ports facilitate seamless integration with computers and lab networks. The included Windows-compatible software further enhances data analysis and reporting, making this analyzer a valuable asset for any quality control or research application.

FAQs of RICE ANALYZER:

Q: How does the RICE ANALYZER count and sort rice grains?

A: The analyzer uses advanced image sensor technology to automatically count and sort rice grains as they are fed onto the sample tray. This method ensures rapid and highly accurate results, minimizing manual effort and reducing human error.Q: What parameters can the RICE ANALYZER measure during analysis?

A: It measures key rice quality parameters, including grain length, thickness, broken percentage, whiteness, and chalkiness. These metrics are essential for reliable grain quality assessment and grading.Q: When and where is using the RICE ANALYZER most beneficial?

A: The analyzer is ideal for quality control laboratories, rice mills, research institutions, exporters, and food distributors in India. Its rapid analysis and data storage capabilities make it suitable for both routine and specialized quality assessments.Q: What process does the analyzer follow for calibration and error management?

A: The RICE ANALYZER features an auto-calibration function, ensuring consistent accuracy for every batch. It is equipped with overload protection and error alarms to promptly notify operators of any issues during operation.Q: How is data managed and exported from the device?

A: Data can be stored internally and easily exported via USB or RS232 ports. The analyzer comes with Windows-compatible software, facilitating convenient data analysis, storage, and reporting on connected computers.Q: What advantages does the automated sample feed provide?

A: Automated sample feeding streamlines operation, allowing for rapid assessment of 5001000g samples within seconds. This increases productivity and ensures even sample distribution for precise analysis.Q: What safety features are integrated into the RICE ANALYZER?

A: The device includes comprehensive safety features such as overload protection and error alarms, which ensure both operator safety and the longevity of the machine.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Agricultural Machines & Tools Category

HOT AIR SEED DRYER CABINET TYPE

Type : Other, Cabinet Type Hot Air Seed Dryer

Usage & Applications : Used for drying various seeds (paddy, wheat, pulses, vegetables, etc.) in seed processing units and research labs

Color : Blue/White or as per manufacturer

Product Type : Seed Dryer Cabinet

Capacity : 100500 kg per batch (varies by model)

Material : Other, Industrialgrade mild steel with powder coating

COMPUTERISED SEED COUNTER

Type : Other, Digital seed counter

Usage & Applications : Seed testing labs, seed production, agricultural research

Color : White & Blue

Product Type : Seed counter equipment

Capacity : Up to 99,999 seeds per batch

Material : Other, ABS plastic, stainless steel disc

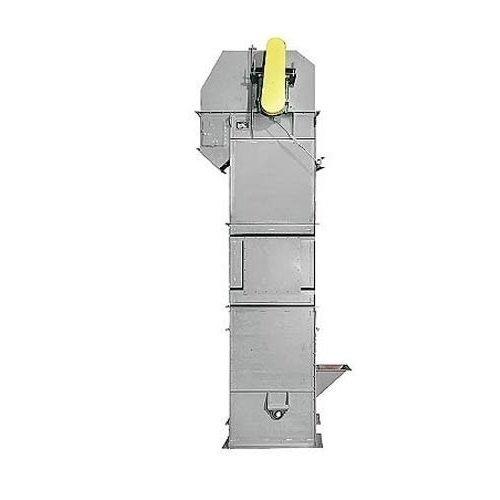

BUCKET ELEVATOR

Type : Other, Bucket Elevator

Usage & Applications : Factories, mills, processing plants, grain terminals, storage facilities

Color : Blue/Grey, as per manufacturers standard

Product Type : Material Handling Equipment

Capacity : 15 Ton/hour (configurable)

Material : Other, Mild Steel or Stainless Steel construction

STEREO ZOOM BINOCULAR MICROSCOPE

Type : Other, Stereo Zoom Binocular Microscope

Usage & Applications : Sample viewing, Dissection, MicroAssembly, Electronics, Gemology

Color : White and Black

Product Type : Binocular Microscope

Capacity : Variable Zoom (0.7x to 4.5x) continuous zoom

Material : Other, Metal Body with Optical Glass

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese