Simple Jib Crane

Simple Jib Crane Specification

- Accuracy

- 5 mm positioning

- Features

- 360-degree rotation, robust construction, easy installation

- Control System

- Lever/Hand operated

- Technology

- Manual lifting and rotation mechanism

- Machine Type

- Jib Crane

- Automation Grade

- Manual

- Surface Treatment

- Painted finish for corrosion resistance

- Accessories Type

- Chain pulley block, hook

- Power Source

- Manual

- Operating Pressure

- Not applicable (manual)

- Type

- Pillar Mounted Jib Crane

- Material

- Mild Steel (MS)

- Function

- Material handling and lifting

- Application

- Warehouses, Workshops, Industrial shops

- Voltage

- Not required (manual operation)

- Swivel

- Full 360-degree rotation

- Crane Mounting

- Floor/Bolted with base plate

- Maximum Lifting Capacity

- 500 kg to 2000 kg (customizable)

- Installation

- Onsite assembly required

- Boom Length

- 2 m to 4 m (as per requirement)

- Operating Environment

- Indoor/Outdoor

- Height of Lift

- Up to 4 meters (customizable)

About Simple Jib Crane

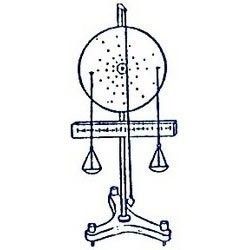

SimpleJib Crane

Consistingof a tubular compression balance, pivoted about an axis fitted to the base. The tie chain has an adjustable anglebracket and fitted with a 10 kg extension balance. Complete on wooden base with1.2 meter jib. Without weights.

Customizable Lifting and Boom Options

This jib crane supports a wide range of lifting requirements, with capacities adjustable from 500 kg to 2000 kg and boom lengths tailored between 2 and 4 meters. Its adaptability ensures it fits seamlessly into different spaces and operations, enhancing productivity for varied application environments.

Manual, Reliable Operation

Engineered for manual operation, the crane eliminates dependence on electric power sources, promoting reliability in any setting. The lever or hand-operated system facilitates precise material positioning (accuracy up to 5 mm) and offers a cost-effective, maintenance-light solution for daily lifting tasks.

Robust Construction for Long-Term Use

Manufactured from durable mild steel with a protective painted finish, this pillar-mounted jib crane delivers both strength and corrosion resistance. The structure offers stability and safety during lifting, making it an excellent choice for warehouse, workshop, and industrial applications.

FAQ's of Simple Jib Crane:

Q: How is the Simple Jib Crane installed?

A: The crane is mounted on the floor using a bolted base plate and requires onsite assembly. Installation is straightforward, typically completed by following the provided instructions and using standard tools. Professional assistance is recommended to ensure secure and optimal setup.Q: What is the process for operating the crane?

A: This jib crane is manually operated using a chain pulley block and hand lever. The operator attaches the load to the hook, lifts using the pulley mechanism, and rotates the boom up to 360 degrees for accurate positioning, all without the need for electric power.Q: Where can this jib crane be used effectively?

A: The crane is designed for both indoor and outdoor environments. It is commonly used in warehouses, workshops, industrial shops, and similar locations where material handling and lifting are routine tasks.Q: What are the main benefits of a manually operated jib crane?

A: Manual operation ensures continued functionality without reliance on electricity, making the crane suitable for locations with limited power access. The design results in lower maintenance requirements, reduced operating costs, and easy control for precise load placement.Q: When should the lifting capacity and boom length be customized?

A: Customizing these features is advisable when you have specific space constraints or unique lifting requirements. Selecting the appropriate capacity (500 kg to 2000 kg) and boom length (2 m to 4 m) ensures that the crane meets your operational needs without compromising safety.Q: What material is used for the construction, and how does it enhance durability?

A: The crane is constructed from high-quality mild steel and finished with a corrosion-resistant paint. This ensures a long lifespan, providing structural strength and resistance to harsh indoor and outdoor environments.Q: How accurate is the positioning of loads with this jib crane?

A: The crane offers positioning accuracy of approximately 5 mm, allowing operators to handle materials safely and precisely during lifting and placement tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Law of Moments Apparatus

Control System : Mechanical, Handoperated

Material : Sturdy Metal Base with Aluminum/Steel Lever Arm and Pan Support

Type : Physics Laboratory Apparatus

Function : Demonstrate Law of Moments (Principle of Levers)

Features : Durable construction, Easy to assemble, Stable base, Graduated scale for precise measurement

Accuracy : High accuracy (typically 0.01 N) for force measurement

Inoculation Chamber

Control System : Manual operation, with provision for optional electrical accessories

Material : Mild Steel / Stainless Steel (as per requirement)

Type : Laboratory Inoculation Chamber

Function : Provides a controlled, contaminationfree environment for microbiological work

Features : Transparent acrylic front; easytoclean interior surfaces; reduced contamination risk; integrated illumination; optional UV lamp for sterilization

Accuracy : High precision with minimal contamination

At wood Machine

Control System : PLC Control System

Material : Stainless Steel and Alloy

Type : Woodworking Machine

Function : Cutting, Shaping and Drilling Wood

Features : High Precision, Durable Structure, Low Maintenance, Energy Efficient

Accuracy : 0.05 mm

D Pharmacy Instrument

Control System : Hand Operated

Material : Stainless Steel

Type : Laboratory Instrument

Function : Pharmaceutical Analysis

Features : Corrosion Resistant, Durable, Easy to Clean

Accuracy : High Precision

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese