Wheel and Differential Axle

Wheel and Differential Axle Specification

- Features

- Corrosion Resistance, High Load Capacity, Enhanced Durability

- Accessories Type

- Bearings and Housings

- Power Source

- Mechanical

- Technology

- Precision Engineering

- Operating Pressure

- Ambient / Not Pressure Driven

- Accuracy

- High Precision

- Control System

- Mechanical

- Machine Type

- Differential Gear System

- Surface Treatment

- Galvanized

- Automation Grade

- Manual

- Type

- Differential Axle with Wheel

- Material

- Alloy Steel

- Function

- Power Transmission and Motion Control

- Application

- Automotive, Heavy Vehicles, Industrial Machinery

- Diameter

- 350 mm (Wheel), 90 mm (Axle)

- Finish

- Smooth Machined

- Load Capacity

- Up to 12 Tons

- Mount Type

- Bolted Flange

- Color

- Silver/Grey

- Manufacturing Standard

- ISO 9001:2015

- Lubrication

- Grease or Oil

- Hardness

- 54-58 HRC

- Tolerance

- ±0.02 mm

- Maintenance

- Low

About Wheel and Differential Axle

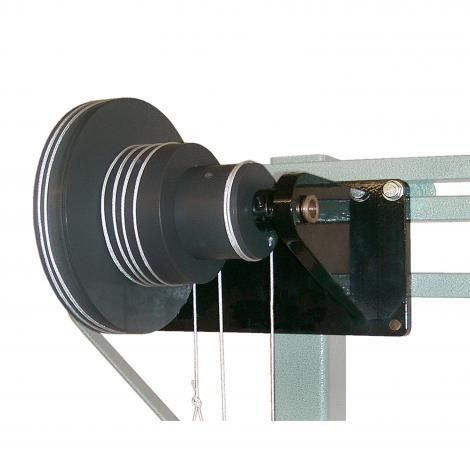

Wheel and Differential Axle

All metalwheel of 30 cm diameter the axle having diameter of 15 & 7.5 omrespectively giving a ratio of 1:2:4 A steel axle passes through the center ofthe wheel which mounted on ball bearing in cast iron brackets reducing frictionto minimum. The base has holes to fix the apparatus on wall Complete withsnatch pulley block, cord and hooks but without weights.

Built for Heavy Duty and Precision

The differential axle with wheel is ideal for demanding applications that require reliable performance under extreme loads. Utilizing advanced precision engineering and manufactured according to ISO 9001:2015 standards, this assembly delivers superior accuracy, enhanced durability, and long-lasting power transmission. Its galvanization and smooth machining guarantee excellent surface protection, making it the preferred choice for heavy vehicles and industrial gear systems where efficiency and robustness are paramount.

Versatile Applications and Superior Design

Suitable for both automotive and industrial settings, this differential axle and wheel assembly is compatible with a variety of machine types, especially those relying on manual, mechanical control systems. The alloy steel construction, high load capacity, and corrosion-resistant treatment ensure dependable service in challenging environments. With a low-maintenance design and provision for both grease and oil lubrication, it significantly reduces downtime and supports continuous operation.

FAQ's of Wheel and Differential Axle:

Q: How is the differential axle with wheel installed in machinery?

A: The assembly features a bolted flange mount for secure and straightforward installation. It can be seamlessly integrated into compatible machine types, requiring only basic mechanical tools and standard installation procedures.Q: What types of lubrication are recommended for this axle and wheel system?

A: You can use either grease or oil for lubricating this system. The selection depends on the operating environment and maintenance schedules, but both options help ensure smooth functioning and prolong component life.Q: When should the maintenance on this differential axle be performed?

A: Although designed for low maintenance, periodic checks according to manufacturer guidelines are recommended. Inspect lubrication levels and the integrity of bearings and housings during routine machinery servicing or based on operational intensity.Q: Where can this product be used effectively?

A: It is highly effective in automotive, heavy vehicle, and industrial machinery settings-anywhere high load capacity and precise motion control are required. Its robust construction suits demanding operational environments.Q: What benefits does the precision engineering provide for this product?

A: Precision engineering ensures high accuracy (0.02 mm), delivering stable power transmission, efficient motion control, and reduced wear. This results in extended operational life and decreased need for repairs or replacements.Q: Which process ensures this wheel and axle assembly's corrosion resistance?

A: The components undergo a galvanizing surface treatment, which provides a protective zinc coating to enhance corrosion resistance, making them suitable for harsh and varied climatic conditions.Q: What makes this product a suitable choice for heavy-duty applications?

A: Its construction from high-hardness alloy steel, ability to handle up to 12 tons of load, and compliance with stringent ISO manufacturing standards ensure exceptional durability, reliability, and performance under demanding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Geared Jib Crane

Automation Grade : Manual

Surface Treatment : Painted with anticorrosive coating for durability

Machine Type : Manual/Geared Jib Crane

Material : Highgrade steel structure

Application : Warehousing, factories, workshops, and industrial applications

Accuracy : High positioning accuracy due to geared rotation

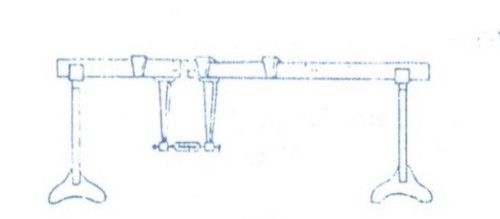

Stresses In Beams Apparatus

Automation Grade : Manual

Surface Treatment : Powder Coated

Machine Type : Bench Top

Material : Mild Steel and Aluminum

Application : Engineering & Technical Education

Accuracy : Highprecision dial gauge

Bending Moment Apparatus

Automation Grade : Manual

Surface Treatment : Powder Coated

Machine Type : Experimental Testing Apparatus

Material : Mild Steel (MS), Stainless Steel (SS)

Application : Educational, Laboratory Use, Engineering Institutes

Accuracy : 1%

Coil Friction Apparatus

Automation Grade : Manual

Surface Treatment : Powder Coated

Machine Type : Bench Top Apparatus

Material : Mild Steel (Frame), Stainless Steel (Coil)

Application : Physics and Engineering Laboratories

Accuracy : 0.5% measurement error

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese