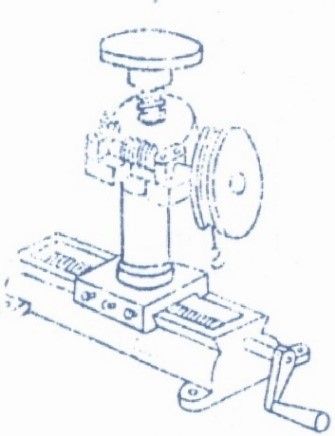

Compound Screw Jack With Transverse Motion

Compound Screw Jack With Transverse Motion Specification

- Automation Grade

- Manual

- Features

- Robust Construction, High Load Bearing Capacity, Smooth Transverse Movement, Corrosion Resistant Finish

- Operating Pressure

- No External Pressure Required (Manual Operation)

- Accuracy

- 0.05 mm

- Accessories Type

- Transverse Motion Plate, Handle Rod

- Control System

- Rotary Screw Mechanism

- Power Source

- Manual/Hand Operated

- Technology

- Manual Mechanical Screw Jack

- Machine Type

- Compound Screw Jack

- Surface Treatment

- Powder Coated / Hardened

- Type

- Compound Screw Jack With Transverse Motion

- Material

- High Grade Mild Steel / Alloy Steel

- Function

- Lifting, Lowering and Precise Positioning

- Application

- Heavy Duty Industrial Uses, Workshop Machinery, Automotive Maintenance

- Maximum Height

- 250 mm (Approx)

- Screw Diameter

- 32 mm (Standard)

- Base Size

- 150 mm x 150 mm

- Load Capacity

- Up to 5 Tons (Customizable)

- Top Plate Size

- 120 mm x 120 mm

- Finish

- Smooth Matte

- Operating Temperature Range

- -10°C to +50°C

- Colour

- Industrial Grey / Custom Colours Available

- Compliant Standards

- IS 4992 / Relevant ISO Standards

- Safety Features

- Overload Protection, Lock Nut Mechanism

- Transverse Travel

- Up to 300 mm (Depending on Model)

- Lubrication Requirement

- Grease Lubrication

About Compound Screw Jack With Transverse Motion

Compound Screw Jack With Transverse Motion

As above butthe whole unit mounted on a sturdy slide. The slide platform is approximately37cm long and is operated by a leading screw with crank handier Weights are notincluded.

Superior Load Capacity and Precision

Offering a load capacity of up to 5 tons, the compound screw jack is ideal for precise and robust lifting tasks. Its transverse travel of up to 300 mm and height adjustment capability (up to 250 mm) make it suitable for demanding industrial settings, ensuring high accuracy positioning within 0.05 mm.

Safety and Compliance Focused

Equipped with overload protection and a lock nut mechanism, this jack prioritizes operator safety. It is engineered in line with IS 4992 and relevant ISO standards, providing peace of mind regarding regulatory compliance and operational integrity during heavy-duty applications.

Versatile Manual Operation

With a rotary screw mechanism and manual handle rod, this jack requires no external power or pressure, making it ideal for environments where portability and flexibility are essential. Its transverse motion plate accessory supports easy side-to-side repositioning, streamlining maintenance and repair processes.

FAQ's of Compound Screw Jack With Transverse Motion:

Q: How does the transverse motion feature of the compound screw jack benefit industrial applications?

A: The transverse motion enables precise lateral positioning alongside vertical lifting, allowing operators to maneuver heavy loads with greater flexibility. This is particularly useful for aligning machinery components and equipment during installation or repair tasks.Q: What safety mechanisms are incorporated in this screw jack?

A: The device is equipped with overload protection and a lock nut mechanism, ensuring that the jack can securely hold loads without risk of accidental lowering or overload-induced failure during operation.Q: Where can the compound screw jack with transverse motion be used?

A: It is widely used in heavy-duty industrial environments, including workshop machinery setups and automotive maintenance, where precise lifting, lowering, and side-to-side adjustments are required.Q: What is the recommended maintenance process for this screw jack?

A: Regular grease lubrication is necessary to maintain smooth operation and extend the jack's life. Periodically inspect moving parts, check the powder-coated or hardened finish for wear, and ensure all safety features are functioning properly.Q: What are the key benefits of the manual rotary screw mechanism?

A: The manual rotary mechanism allows for precise and controlled movement without the need for external power sources, making operation straightforward, portable, and suitable for locations where electric or hydraulic systems may not be available.Q: Can the load capacity or colour be customized?

A: Yes, the load capacity can be tailored according to specific application requirements, and the jack is available in industrial grey or other custom-coloured finishes to suit organizational preferences.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Winch Crab Double Purchase

Accessories Type : Steel Rope Drum, Hooks

Type : Winch Crab

Control System : Hand Operated/Manual Controls

Accuracy : High Load Positioning Precision

Function : Lifting and Lowering Loads

Material : Mild Steel

Pharmacy Lab Equipment

Accessories Type : Standard Lab Accessories Included

Type : Pharmacy Lab Equipment

Control System : Digital and Analog Controls

Accuracy : High Precision (0.01%)

Function : Analysis and Testing of Pharmaceutical Samples

Material : Stainless Steel & Glass

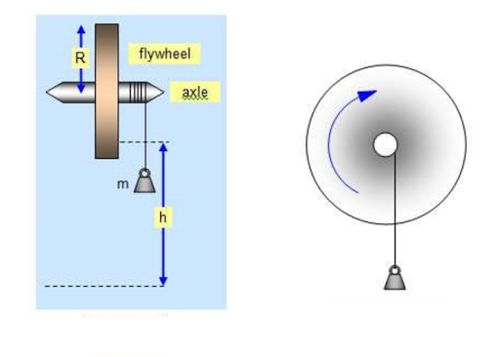

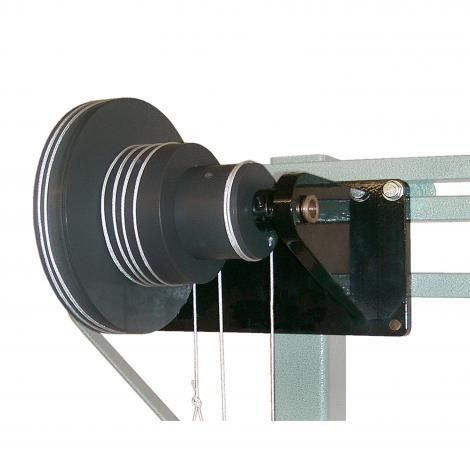

Moment of Inertia of Flywheel

Accessories Type : Cord, Weights, Scale

Type : Laboratory Instrument

Control System : Mechanical

Accuracy : High

Function : Determine Moment of Inertia

Material : Cast Iron

Wheel and Differential Axle

Accessories Type : Bearings and Housings

Type : Differential Axle with Wheel

Control System : Mechanical

Accuracy : High Precision

Function : Power Transmission and Motion Control

Material : Alloy Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese