Torsion Apparatus (Clamp Pattern)

Torsion Apparatus (Clamp Pattern) Specification

- Control System

- Hand-operated Clamp & Scale

- Accessories Type

- Measuring Scale, Test Rods, Clamps

- Accuracy

- High Precision (0.5%)

- Surface Treatment

- Powder Coated & Polished

- Technology

- Mechanical Measurement

- Automation Grade

- Manual

- Features

- Rigid Construction, Corrosion Resistant, Easy to Use

- Power Source

- Manual

- Machine Type

- Bench-top Experimental Apparatus

- Type

- Clamp Pattern

- Material

- Stainless Steel, Mild Steel & Brass Components

- Function

- Demonstrates Torsion, Mechanical Testing

- Application

- Laboratory, Engineering Education

- Voltage

- Not Required (Manual Operation)

- Packing

- Supplied in strong packaging for secure transport

- Finish

- Smooth Powder Coated & Polished Metal

- Usage

- Suitable for demonstration, practical and research work

- Clamping Mechanism

- Screw clamp arrangement with brass jaws

- Least Count of Scale

- 1 mm

- Rod Material

- Mild Steel Polished Rod

- Wire Diameter Range

- 0.28 mm to 0.5 mm

- Maximum Wire Length

- 100 cm

- Dimensions

- Base Size Approx. 45 x 10 cm

- Base Material

- Heavy Cast Iron Base with leveling screws

- Wire Material

- Torsion (mild steel) wire supplied

- Weight

- Approx. 6 kg

About Torsion Apparatus (Clamp Pattern)

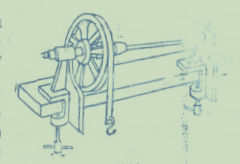

Torsion Apparatus (Clamp Pattern)

It is more convenient to observe thefort ion produced in rods of varying length be tween 1 mater to 2 mater. Theunit includes two heavy clamps, one of which is fitted with a wheel graduatedin 90 0-90 degrees and can be read to 0.1 degrees and can by a venire device, aconcentric chuck is also fitted with the wheel. The other bracket carries achuck provided with three nipping screw a. Complete with 4 rods of about 6 mm,8 mm, 9,5 mm and 125 mm. din. hank and belt, but without weights.

Robust Construction & Material Quality

Built from heavy cast iron, polished mild steel, and brass components, the Torsion Apparatus delivers exceptional durability and stability during measurements. The powder-coated and polished surfaces protect against corrosion, ensuring reliable operation for years, even in busy laboratory settings.

Highly Accurate Mechanical Measurements

Engineered for high precision, the device offers accuracy within 0.5%. The measuring scale features a least count of 1 mm, making it suitable for experiments requiring detailed readings. This ensures students and researchers can rely on its readings for educational demonstrations and practical investigations.

Versatile Laboratory Applications

This apparatus is tailor-made for laboratory experiments, engineering education, and research requiring the study of torsional properties. Its simple, manual operation requires no external power, making it a convenient and low-maintenance solution for bench-top experimental setups.

FAQs of Torsion Apparatus (Clamp Pattern):

Q: How do I use the Torsion Apparatus for mechanical testing?

A: Begin by securing the torsion wire firmly using the screw clamp arrangement with brass jaws. Adjust the leveling screws for stability, set the desired wire length (up to 100 cm), and use the hand-operated clamp and scale to apply and measure the torsional force. Ensure the measuring scale is read at 1 mm precision for accurate data collection.Q: What benefits does the cast iron base and powder-coated finish provide?

A: The heavy cast iron base ensures excellent stability and rigidity during experiments, reducing measurement errors. The powder-coated and polished finish offers enhanced corrosion resistance, extending the devices service life, especially in demanding laboratory environments.Q: Where is this Torsion Apparatus most commonly used?

A: This apparatus is widely used in educational laboratories, engineering institutes, and research facilities across India and internationally. Its robust design and high accuracy make it ideal for teaching mechanical properties and conducting rigorous experimental research.Q: When should I use the Torsion Apparatus in my curriculum or research?

A: You should incorporate this device when studying topics related to torsion, shear modulus, or material strength in laboratory exercises or research projects. Its versatility allows demonstrations, practical assessments, and material property investigations at various educational levels.Q: What is the process for changing the torsion wire in the apparatus?

A: To replace the torsion wire, first loosen the screw clamp arrangement, carefully remove the old wire, and insert a new steel wire (0.28 mm to 0.5 mm diameter). Secure it using the brass jaws, ensuring its taut and properly aligned before beginning new tests.Q: How does the manual operation benefit laboratory usage?

A: Manual operation eliminates the need for an external power source, making the apparatus portable and reliable in any laboratory. The simple, hand-operated controls also allow precise user intervention and adjustment during experiments.Q: What is included in the packaging when purchasing this equipment?

A: The Torsion Apparatus is supplied with torsion wire (mild steel), measuring scale, test rods, clamps, and comes packed securely in strong packaging for safe transport, making it suitable for distributors, exporters, and educational institutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

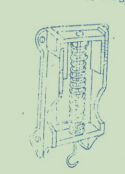

Compression of Coiled Springs

Accuracy : 0.01 mm

Material : Stainless Steel

Surface Treatment : Polished

Function : Absorbs shock and returns to original position after compression

Control System : Digital Display

Accessories Type : Compression Plates, Digital Gauge

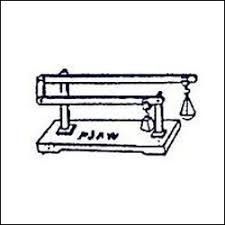

Compound Lever

Accuracy : High Force Transfer Precision

Material : HighGrade Steel

Surface Treatment : Polished / AntiCorrosive Coating

Function : Transfers Force with Mechanical Advantage

Control System : Mechanical

Accessories Type : Lever Assembly

Geared Jib Crane

Accuracy : High positioning accuracy due to geared rotation

Material : Highgrade steel structure

Surface Treatment : Painted with anticorrosive coating for durability

Function : Material handling and load lifting

Control System : Hand operated gear mechanism

Accessories Type : Swivel arm, chain pulley block, rotating boom

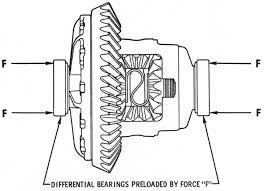

Wheel and Differential Axle

Accuracy : 0.01 mm

Material : High Grade Steel

Surface Treatment : Powder Coated

Function : Transmits Power and Movement

Control System : Mechanical

Accessories Type : Axle Components, Bearings

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese