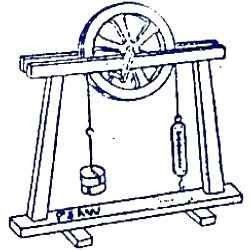

Universal Force Table

Universal Force Table Specification

- Machine Type

- Educational Lab Equipment

- Surface Treatment

- Powder Coated

- Automation Grade

- Manual

- Accessories Type

- Brass Pulleys, Slotted Weights, Nylon Strings

- Accuracy

- High Precision Angle Measurement

- Technology

- Classical Mechanics Apparatus

- Control System

- Mechanical

- Features

- 360 Rotatable Tabletop, Graduated Circle, Robust Construction

- Power Source

- Non-Electric

- Type

- Universal Force Table

- Material

- Aluminum Alloy Top, Stainless Steel Accessories

- Function

- Vector Addition and Resolution Demonstration

- Application

- Physics Laboratory Experimentation

- Maximum Load Capacity

- Up to 1 kg distributed

- Weight Set

- Brass/steel weights with hooks (typically 50g, 100g, 200g increments)

- Platform Diameter

- 30 cm (approx.)

- Pointer & Clamp

- High-contrast, detachable pointer with rigid clamp

- Number of Pulleys

- 3 (standard, extendable to 4)

- Maintenance

- Rust-resistant, easy to clean platform

- Scale Graduation

- Marked at 1° intervals

- Leveling Arrangement

- Three-point leveling adjustable screws

- Pulley Material

- Low-friction plastic or brass

- Mounting Base

- Anti-skid rubber feet for stable operation

About Universal Force Table

Universal Force Table

Forexperimentally verifying the laws of triangle. Parallelogram and polygon offorces. Comprising of a circular 40 cm. diameter aluminum disc, graduated into360 degrees. Complete with levelling screws, clamping device to fix the tableat any desired angle, five sliding clamp pulleys, central ring, string and fivesets of iron nickelled slotted weights, each set containing nine weights andone hanger of 50gms, each.

Precision and Versatility in Experimentation

The Universal Force Table stands out with its high-accuracy graduated circle and a robust, rotatable platform. Designed for manual operation, it accommodates up to four pulleys and a variety of weight combinations, making it suitable for a broad array of vector resolution and addition experiments. Its sturdy construction ensures safety and reliability for repeated educational use.

Built for Stability and Long-Term Use

With anti-skid rubber feet and a powder-coated finish, the table maintains firm placement during intensive experiments. The rust-resistant, easy-to-clean aluminum alloy platform complemented by stainless steel accessories ensures sustained durability, while adjustable leveling screws help achieve optimal calibration in any laboratory setting.

FAQs of Universal Force Table:

Q: How is the Universal Force Table primarily used in a physics laboratory?

A: The Universal Force Table is utilized to visually and experimentally demonstrate concepts of vector addition and resolution. Students attach weights to pulleys and observe how force vectors interact, making it an invaluable tool for practical learning in classical mechanics.Q: What is the process of setting up the Universal Force Table for an experiment?

A: To set up, level the table using the three-point leveling screws and attach the required number of pulleys using the rigid clamps. Place the provided weights on the nylon strings and adjust the angles using the graduated scale for precise vector measurements.Q: When should additional pulleys be used on the table?

A: Additional pulleys should be added when experiments require the demonstration or calculation of more than three force vectors. The table can be expanded to accommodate up to four pulleys, allowing for greater experimental versatility.Q: Where can the Universal Force Table be effectively installed?

A: This apparatus is best installed in educational laboratories, schools, colleges, universities, or any learning space focused on physics. Its compact size and anti-skid feet make it suitable for flat, stable surfaces in a controlled environment.Q: What are the benefits of using rust-resistant, powder-coated components?

A: Rust-resistant, powder-coated surfaces ensure long-lasting durability and minimal maintenance. This helps the force table retain its accuracy and appearance over years of frequent use, reducing the need for frequent repairs or replacements.Q: How does the anti-skid mounting base contribute to experimentation?

A: The anti-skid rubber feet stabilize the apparatus, preventing unwanted movement during experiments. This promotes accurate data collection and enhances safety by minimizing the risk of accidental slips.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Pharmacy Lab Equipment

Power Source : Electric

Features : Corrosion Resistant, Easy to Clean, Durable

Material : Stainless Steel & Glass

Control System : Digital and Analog Controls

Application : Pharmacy Colleges, Pharmaceutical Labs

Technology : Advanced Laboratory Instrumentation

Ropo Brake and Dynamometer

Power Source : Electric

Features : High Precision, User Friendly, Low Maintenance, Durable

Material : High Grade Steel and Cast Iron

Control System : Digital Display with PLC Control

Application : Automobile, Industrial Machinery, Laboratory Testing

Technology : Electromagnetic Brake System

PCB Designing Lab

Power Source : Electric

Features : High Precision, User Friendly Interface, MultiLayer Capability

Material : FR4, Copper Clad

Control System : PCBased (Software Driven)

Application : Electronics, Educational Institutes, R&D Labs

Technology : PCB Designing and Prototyping Laboratory Technology

Winch Crab Double Purchase

Power Source : Manual (HandOperated)

Features : High Strength Construction, Corrosion Resistant, Sturdy Design

Material : Mild Steel

Control System : Hand Operated/Manual Controls

Application : Industrial Material Handling

Technology : Double Purchase Mechanism

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese