Compound Screw Jack

Compound Screw Jack Specification

- Automation Grade

- Manual

- Accuracy

- High Precision

- Machine Type

- Lifting Device / Jack

- Features

- Robust Construction, High Load Capacity, Durable and Corrosion Resistant, Easy Operation

- Accessories Type

- Handle, Top Plate

- Power Source

- Manual

- Operating Pressure

- Not Applicable (Mechanical)

- Control System

- Hand Operated

- Technology

- Mechanical Lifting Device

- Surface Treatment

- Painted / Powder Coated

- Type

- Compound Screw Jack

- Material

- Mild Steel

- Function

- Heavy-duty Lifting and Positioning

- Application

- Construction, Industrial, Mechanical Workshops, Structural Maintenance

- Operating Temperature

- -10°C to 60°C

- Maintenance

- Low maintenance, easy lubrication

- Thread Type

- Trapezoidal Thread for higher load efficiency

- Safety

- In-built locking and anti-drop mechanism

- Maximum Lift Height

- 150 mm to 600 mm

- Base Type

- Flat / Flanged Type with Reinforcement

- Color

- Red, Yellow, Blue (custom options may be available)

- Lifting Capacity

- 10 Ton, 20 Ton, 30 Ton, up to 100 Ton (as per model)

- Weight

- Varies with capacity, typically 10 kg to 50 kg

About Compound Screw Jack

Compound Screw JackConsistingof a jack screw of 4 T.P.l. and double start carrying load platform. The nut ofthe screw is fitted on a pedestal bearing and is keyed to a worm gear of 40teeth operated by a worm screw. The spindle of the warm screw is provided withan effort wheel of 15 cm diameter. Weights are not included

Exceptional Lifting Capabilities

The Compound Screw Jack stands out for its high load capacity, supporting between 10 and 100 tons based on model selection. Its robust mild steel construction and reinforced baseavailable in both flat and flanged designsdeliver stability and safety during heavy lifting and positioning tasks. This makes it ideal for demanding environments where reliability is crucial.

Precision and Safety

Boasting advanced features like a trapezoidal threaded spindle and built-in anti-drop and locking mechanisms, this jack ensures enhanced load efficiency and operator safety at all times. The high-precision mechanism guarantees accurate lifting, while its manual, hand-operated control system offers intuitive and secure usability.

Durability and Low Maintenance

Finished in high-quality painted or powder-coated surfaces, the Compound Screw Jack is engineered for durability and corrosion resistance, suitable for both indoor and outdoor use. Its low-maintenance design allows for easy lubrication, reducing downtime and extending the lifespan of the equipment. Multiple color options and easy-to-use accessories, such as handle and top plate, further enhance functionality.

FAQs of Compound Screw Jack:

Q: How does the compound screw jack achieve high lifting efficiency?

A: The compound screw jack employs a trapezoidal thread shaft, which offers greater load efficiency and smooth manual operation. This design minimizes friction during lifting, allowing the device to handle heavy loadsranging from 10 to 100 tonseffectively and safely.Q: What maintenance is required for the compound screw jack?

A: The jack is designed with low maintenance in mind. Routine lubrication of moving parts is typically all thats necessary to keep it functioning smoothly. Its painted or powder-coated surface adds to corrosion resistance, making upkeep straightforward even in challenging environments.Q: When should I use a flat base versus a flanged base jack?

A: A flat base is ideal for stable, flat surfaces, offering reliable support in static positions. A flanged base with reinforcement is better suited for environments that may require bolting down the jack for added stability, especially in high-load applications or uneven terrains.Q: Where can the compound screw jack be utilized effectively?

A: This lifting device is suitable for a broad range of applications, including construction sites, industrial plants, machine workshops, and structural maintenance projects. Its heavy-duty and manual operation make it adaptable to environments where power sources are unavailable or heavy machinery is impractical.Q: What safety features are incorporated in the design?

A: The compound screw jack includes in-built locking and anti-drop mechanisms to prevent unexpected lowering of loads, ensuring the safety of both operators and equipment during use. The robust structure and precision threads further contribute to safe operation under high loads.Q: How do I operate the compound screw jack manually?

A: The jack is operated using a specially designed handle that turns the trapezoidal thread spindle, raising or lowering the load. This manual control ensures precise adjustments and easy handling, without the need for external power sources.Q: What are the benefits of using this jack over hydraulic alternatives?

A: Compared to hydraulic lifting devices, the compound screw jack offers greater reliability in remote or power-limited settings, reduced maintenance needs, and a robust mechanism free from fluid leaks or pressure issues. Its mechanical design ensures high precision and longevity for repetitive, heavy-duty lifting tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

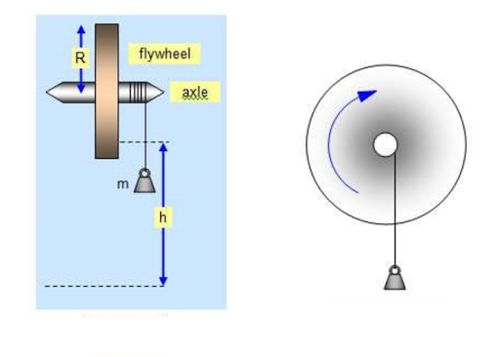

Moment of Inertia of Flywheel

Accessories Type : Cord, Weights, Scale

Control System : Mechanical

Technology : Mechanical

Surface Treatment : Polished

Automation Grade : Manual

Accuracy : High

Torsion Apparatus (Clamp Pattern)

Accessories Type : Measuring Scale, Test Rods, Clamps

Control System : Handoperated Clamp & Scale

Technology : Mechanical Measurement

Surface Treatment : Powder Coated & Polished

Automation Grade : Manual

Accuracy : High Precision (0.5%)

Link Polygon Apparatus

Accessories Type : Complete with weights, pulleys, and instruction manual

Control System : Hand Operated

Technology : Mechanical Demonstration Apparatus

Surface Treatment : Powder Coated

Automation Grade : Manual

Accuracy : High Precision

Reversible Pendulum

Accessories Type : Set Includes Weights, KnifeEdges, Adjustable Bracket, and Rigid Stand

Control System : Mechanical Adjustable KnifeEdges

Technology : Precision Mechanical

Surface Treatment : Powder Coated Finish

Automation Grade : Manual

Accuracy : Up to 0.001 s in time measurement

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese