Cranked Compound Lever

Cranked Compound Lever Specification

- Operating Pressure

- Atmospheric

- Accuracy

- High mechanical precision

- Features

- Robust design, durable construction, efficient force application

- Surface Treatment

- Corrosion-resistant finish

- Control System

- Lever operated

- Accessories Type

- Assembly component

- Technology

- Cranked compound lever mechanism

- Automation Grade

- Manual

- Machine Type

- Manual/mechanical machine systems

- Power Source

- Manual (hand operated)

- Type

- Mechanical lever

- Material

- Mild steel

- Function

- Force multiplication and motion transmission

- Application

- Industrial machinery and heavy load handling

- Weight

- Depends on lever size and material thickness

- Mounting Type

- Bolt-on or weld-on

- Finish Color

- Industrial black or grey

- Operating Temperature Range

- -10°C to 60°C

- Lever Arm Length

- Customizable as per application

- Handle Type

- Curved ergonomic handle for better grip

- Maintenance

- Low maintenance required

- Load Capacity

- Up to 2 tons (can vary with size)

About Cranked Compound Lever

Application Versatility and Media Adaptability

Designed for use in manual and mechanical machine systems, the Cranked Compound Lever delivers exceptional force multiplication and motion transmission on industrial machinery. Its robust construction allows installation on bolt-on or weld-on surfaces, making it highly adaptable at various application sites, including factories, workshops, and assembly units. Compatible with atmospheric pressure media, it operates efficiently within industrial-grade environments to handle demanding mechanical tasks.

Domestic Distribution and Premium Supply Services

Supported by a reliable goods transport network, the Cranked Compound Lever ensures prompt arrival across India's main domestic markets. Our supply ability meets large-scale requirements, and a premium sample policy gives clients confidence in product performance before bulk purchase. Whether for manufacturers or traders, we prioritize seamless delivery and transparent logistics, ensuring all assembly components reach your location swiftly and securely.

FAQ's of Cranked Compound Lever:

Q: How can the lever arm length be customized for different applications?

A: The lever arm length can be tailored to your specific application needs, ensuring optimal force multiplication and motion transmission for machinery or heavy load handling tasks.Q: What mounting options are available for the Cranked Compound Lever?

A: This lever offers flexibility in installation with both bolt-on and weld-on mounting types, allowing secure attachment to various surfaces and equipment bases.Q: When is it recommended to use the curved ergonomic handle?

A: The curved ergonomic handle is always recommended as it provides enhanced grip and operator comfort, especially during extended or repetitive manual operations.Q: Where can this lever be applied within industrial environments?

A: It is suitable for use in factories, workshops, assembly lines, and other environments that require machinery or heavy load manipulation. The corrosion-resistant finish ensures reliability in demanding settings.Q: What is the process for maintaining the Cranked Compound Lever?

A: Routine inspection and occasional cleaning are typically sufficient, thanks to its low maintenance design and corrosion-resistant surface treatment.Q: What are the main benefits of choosing this lever for force applications?

A: Users benefit from high mechanical precision, robust efficiency, and durable construction, ensuring reliable performance for force multiplication and motion transmission in manual operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Simple Jib Crane

Material : Mild Steel (MS)

Machine Type : Jib Crane

Automation Grade : Manual

Application : Warehouses, Workshops, Industrial shops

Function : Material handling and lifting

Power Source : Manual

Structural mechanics apparatus

Material : Mild Steel and Aluminum

Machine Type : Bench Top Apparatus

Automation Grade : Manual

Application : Laboratory, Research, Academic Institutes

Function : Demonstrates Structural Mechanics Principles

Power Source : Not Electric, Operated Manually

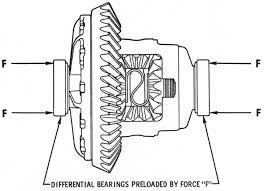

Wheel and Differential Axle

Material : High Grade Steel

Machine Type : Transmission System

Automation Grade : Manual and SemiAutomatic

Application : Automobile, Machinery, Industrial Equipment

Function : Transmits Power and Movement

Power Source : Mechanical Drive

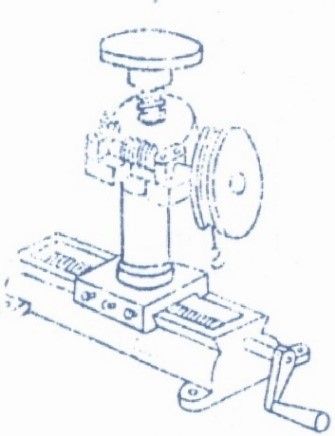

Compound Screw Jack With Transverse Motion

Material : High Grade Mild Steel / Alloy Steel

Machine Type : Compound Screw Jack

Automation Grade : Manual

Application : Heavy Duty Industrial Uses, Workshop Machinery, Automotive Maintenance

Function : Lifting, Lowering and Precise Positioning

Power Source : Manual/Hand Operated

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese